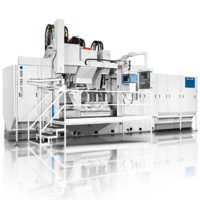

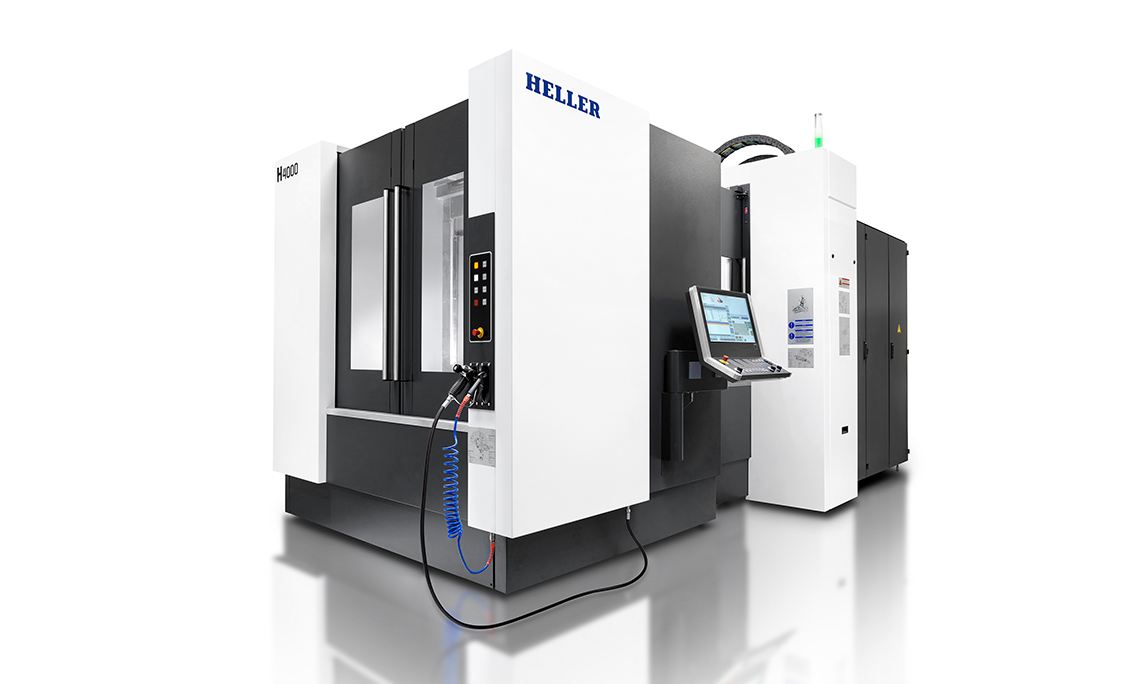

Crossbed and travelling column in gate design

- high stability and damping in the force flow through topology-optimised cast iron structural components

- thermosymmetrical design and optimal force flow

- broad range of rugged machining units

- wide selection of tool magazines, in chain-type or rack-type design for rapid tool provisioning

- tool changer with two NC axes for fastest automatic tool change

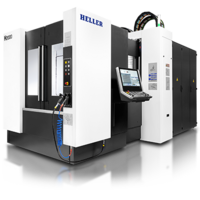

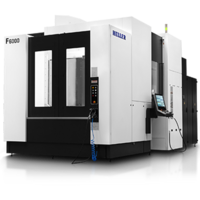

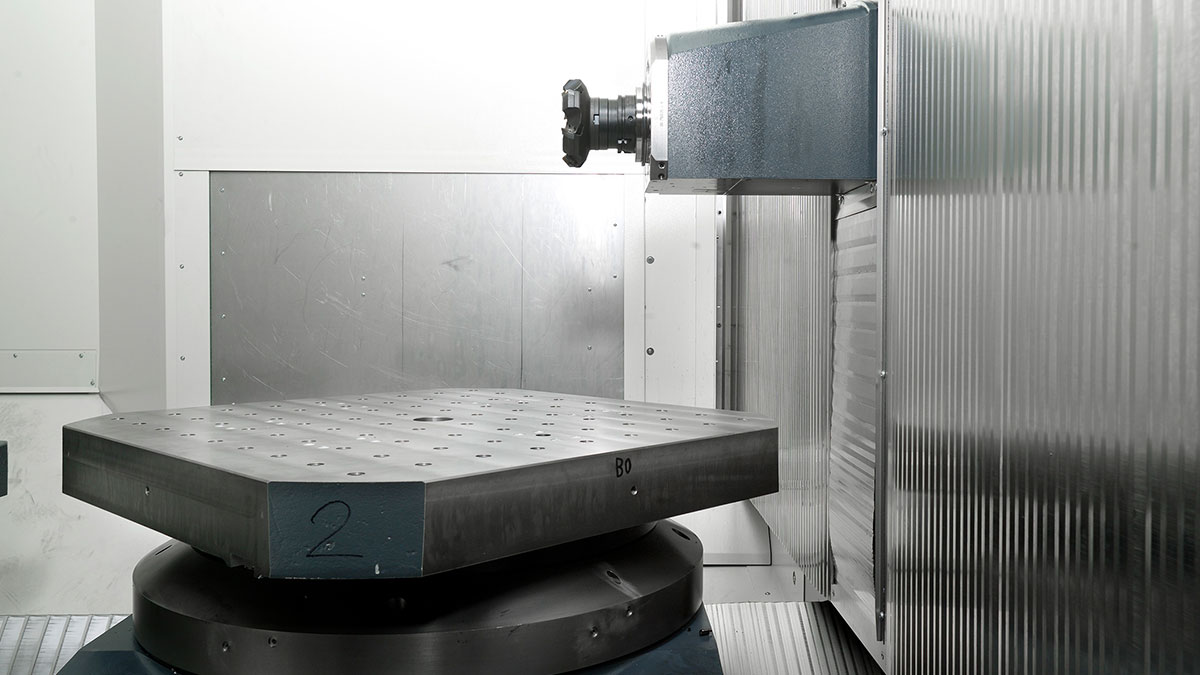

4-axis kinematics with horizontally arranged spindle

- machine bed supports the X- and Z-axes in crossbed arrangement

- machine column traverses in X-direction and supports the machining unit

- machining unit traverses in Y-direction with compact and robust integration into the machine column

- rotary table moves in Z-direction and performs the feed motion

- NC rotary table (rotary axis B) continuously rotates the workpiece (360,000 x 0.001°)

Anti-friction linear guideways and stable YRT bearing in rotary table

- linear axes with roller guides driven by ball screws for high feed forces

- direct, absolute measuring systems with glass scales for maximum precision and minimal positioning tolerance

- PRO equipment package available as an option, featuring maximum rapid traverse speed, higher clamping load and significantly reduced positioning tolerances (H 2000, H 4000)

- SPEED equipment package available as an option, for maximum rapid traverse speed and minimal idle times

- NC rotary feed table with large YRT bearing and automatic clamping for maximum stability and high tilting moments

- NC rotary feed table with gear drive for high torque and damping performance

- NC rotary feed table with direct drive for high dynamics and rapid positioning (standard on H 2000 and H 4000)

- excellent milling behaviour even in the upper stroke positions thanks to the optimised design of the drive train

Machining units

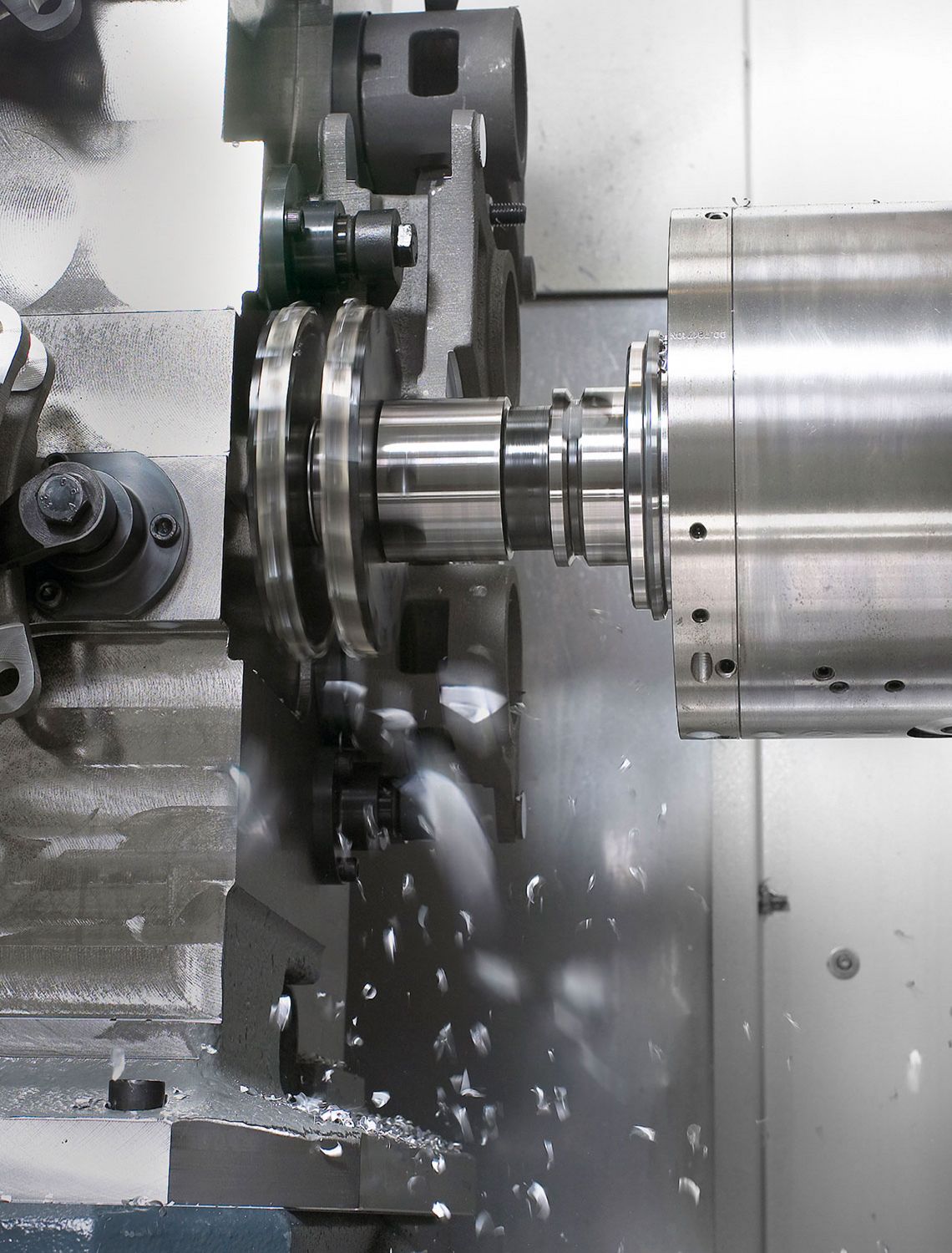

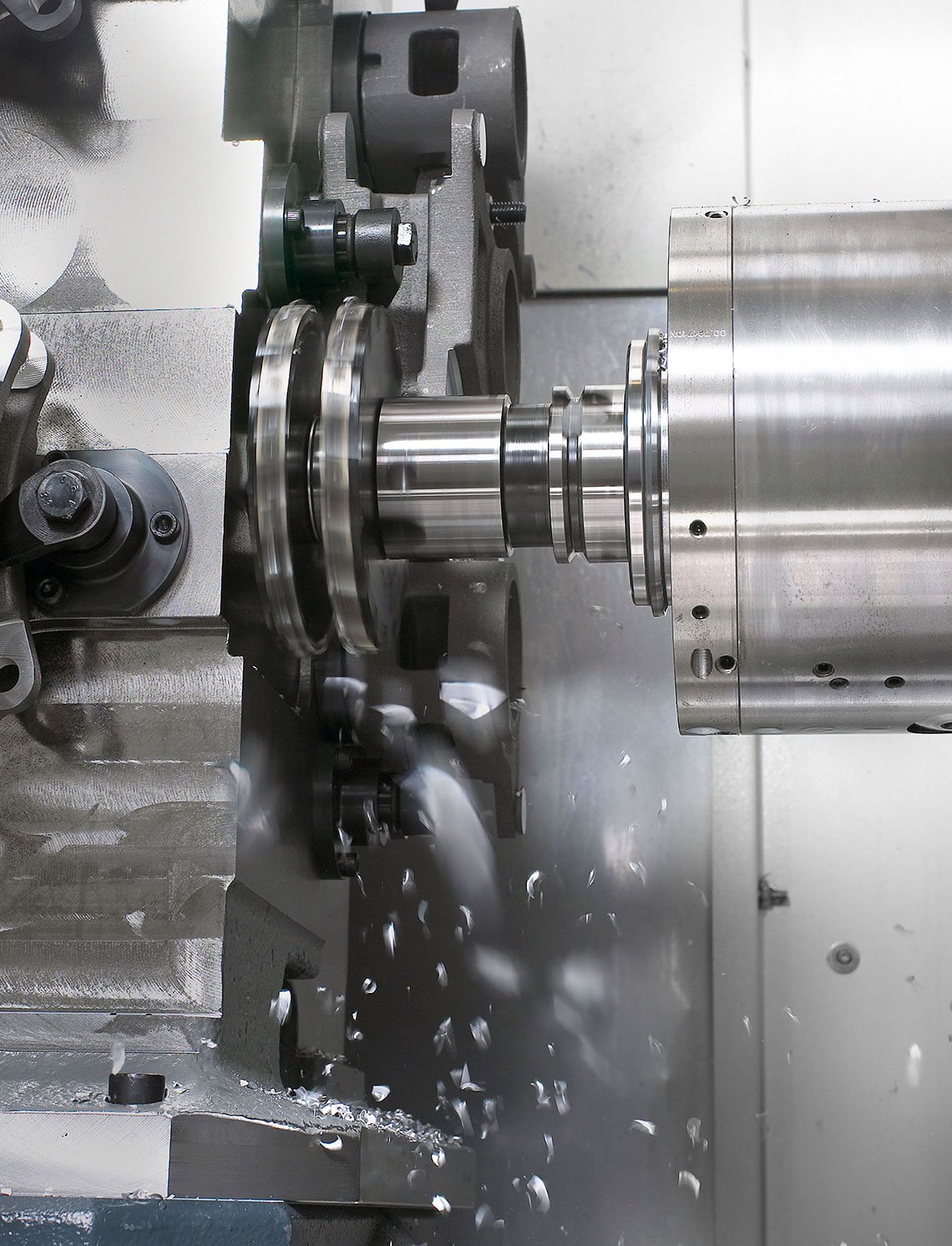

Spindles “Made by HELLER” are among the highlights of our H series 4-axis machining centres. Our in-house manufacturing expertise ensures that they deliver the highest machining quality, guaranteeing process stability and maximum cutting performance. Special advantage: the HELLER zero-spindle system. In the event of a failure, the machining spindle can be replaced quickly and easily.

Robust machining units

- H 2000 – H 4000: 4 machining units with HSK-A 63 tool shank

- H 5000 - H 10000: 3 machining units with INLINE spindles and 3 machining units with gearbox, HSK-A 100 tool shank

- H 8000 / H 10000: 3 machining units with INLINE spindles and HSK-A 63 tool shank

- H 14000 / H 16000: 5 machining units with HSK-A 100 tool shank

- compact overall design and robustly dimensioned spindle bearings for maximum cutting performance

- thermal stability and precision thanks to permanent cooling: precision cooling unit and thermal growth compensation of

the spindle - robust cast iron guide slide with high dynamic rigidity and damping

- slim spindle neck for perfect reach into the workpiece

- horizontal spindle for optimal chip fall

Quick and easy spindle exchange with cost advantages

- easy replacement without time-consuming fine adjustment with INLINE spindle set to zero dimension

- short repair times ensure maximum machine availability

- cost-effective solution for low TCO (Total Cost of Ownership)

- reduced spare parts costs due to the integrated zero spindle technology

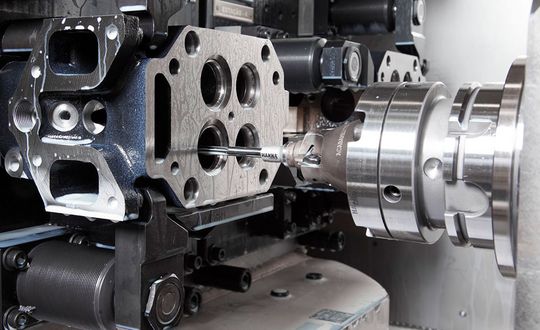

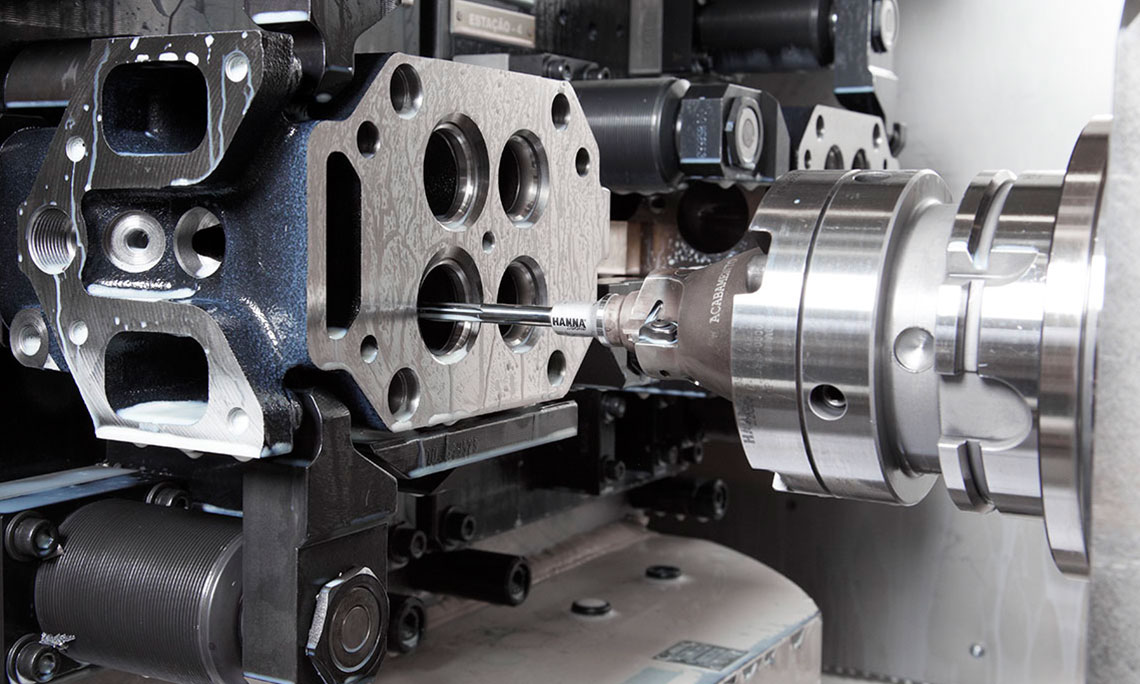

HELLER attachment head support (MSK)*

- for the use of attachment heads, e.g. angular heads

- enlarged support base with three-point support

- integrated torque pickup and media transfer

HELLER attachment head additional clamping*

- for additional clamping of attachment heads on the attachment head support

- optimal stability when using attachment heads and under high process forces

HELLER facing slide system*

- for automatic adjustment of actuating tools

- actuation with a full-fledged NC axis (U) integrated in the machine control

- ideal for contour boring or facing operations

- available for machining units with HSK tool shank

* not available for all machining units

Tool management

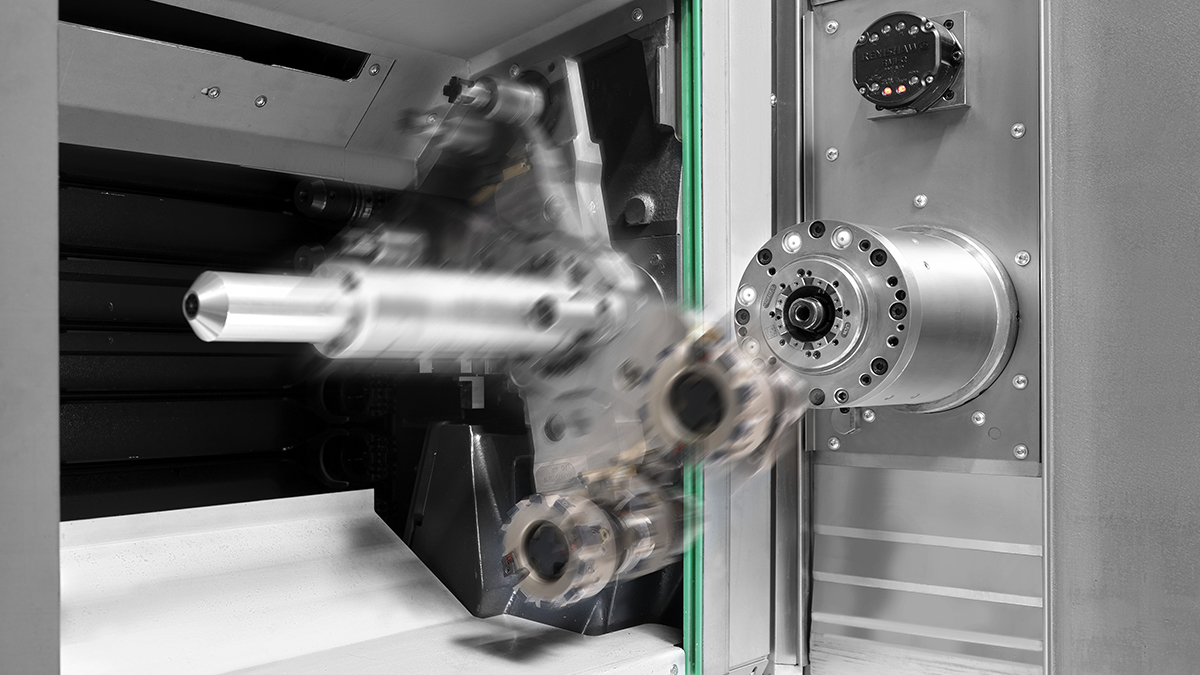

Short setup and idle times are exactly what you can expect from our H series 4-axis machining centres. The tool changer with two NC axes ensures maximum precision and optimised motion sequences for minimal tool change times. Combined with high axis dynamics, this results in short chip-to-chip times.

Rapid tool provisioning

- 4 chain-type magazines with up to 240 storage places for H 2000 and H 4000

- 3 chain-type magazines with up to 150 storage places for H 5000 – H 16000

- sturdy tool holders mounted on both sides of a double chain for optimised traversing dynamics of the chain

- tool provisioning during machining for short tool-to-tool times

- rapid tool change for short chip-to-chip times

- two NC axes with lift/swivel principle for high dynamics and long-term precision

- robust double gripper for secure handling of heavy tools and high moment loads

- integrated tool provisioning place for preparation of the next tool during machining and short tool-to-tool times

High storage capacity

- 2 rack-type magazines with 324/498 places for machines with HSK-A 63

- 4 rack-type magazines with up to 425 places for machines with HSK-A 100

- compact footprint resulting from the extremely space-saving arrangement alongside the machine (H 2000 – H 10000)

- tool handling with highly dynamic loader for rapid tool provisioning

- rapid tool change for short chip-to-chip times

- two NC axes with lift/swivel principle for high dynamics and long-term precision

- robust double gripper for secure handling of heavy tools and high moment loads

- ergonomic operating panel at the tool setting station

- tool setting station with integrated rotary station offering multiple positions for tool loading during machining

- loading of tool sets via mobile rack with manual drive or AGV support

Fast tool change for short chip-to-chip times

- two NC axes with lift/swivel principle for high dynamics and long-term precision

- robust double gripper for secure handling of heavy tools and high moment loads

- integrated tool provisioning place for preparation of the next tool during machining and short tool-to-tool times

Workpiece management

Our H series 4-axis machining centres virtually know no limits when it comes to workpiece size and weight. The machine’s pallet changer concept allows a clamping load of up to 8 tonnes. Even with workpieces of this weight, the HELLER H series operates with a high level of precision.

Automatic Pallet Changer

- automatic pallet changer with lift/swivel principle

- fork-type design with four-point support and robust, hydraulic drive enables high maximum clamping load

- fork shaped lift-and-swivel bridge (optional) ensures optimal force application to machine pallets

- Universal system (H 2000 / H 4000) for full compatibility with HF

- consistently high tool change accuracy due to robust alignment elements and extensive blow-off of functional surfaces

- machine pallets with DIN hole pattern and standardised alignment elements for rapid mounting of clamping fixtures

- hydraulic pallet clamping for secure hold, even under high process forces

- standardised media interfaces for connecting hydraulic clamping fixtures through the centre of the pallet (option)

- preparation with 7-point media interface and MSS-READY, enabling easy retrofitting of all media interface variants

Supply and disposal

Milling inevitably produces chips. This is especially true for the H series 4-axis machining centres: these extremely robust and reliable machining centres are made for production. Wherever chips are produced, we provide efficient disposal solutions to ensure consistently high precision.

Central media supply area on the rear of the machine

- easy maintenance with optimal accessibility, all supply units clearly visible at a glance

- central oil-air lubrication for key components

- sealing air and targeted blow-off of interfaces ensure consistently smooth machine operation

- media interface for hydraulic workpiece clamping with up to 200 bar (option)

- compressed air and water gun integrated into the machine housing at the workpiece loading station

Effective cooling lubricant supply and filtration

- coolant units: paper band filter or backflush filter with high tank volumes available as options

- internal coolant supply (IKZ) through the tool with 50 bar high pressure (option: 70 bar with frequency converter (FU))

- internal coolant supply with up to 7 pressure steps freely programmable via the NC program

- external tool cooling (AKZ) through spindle-integrated flushing nozzles

- integrated work area shower with adjustable nozzles for optimal flushing of the work area and cooling of the workpiece

Options

- coolant cooler for high thermal stability and precision

- coolant temperature control unit

- automatic filling of the coolant unit

- oil skimmer for separation of foreign oil from the cooling lubricant tank

- internal coolant supply IKZ 70 bar with frequency converter (FU)

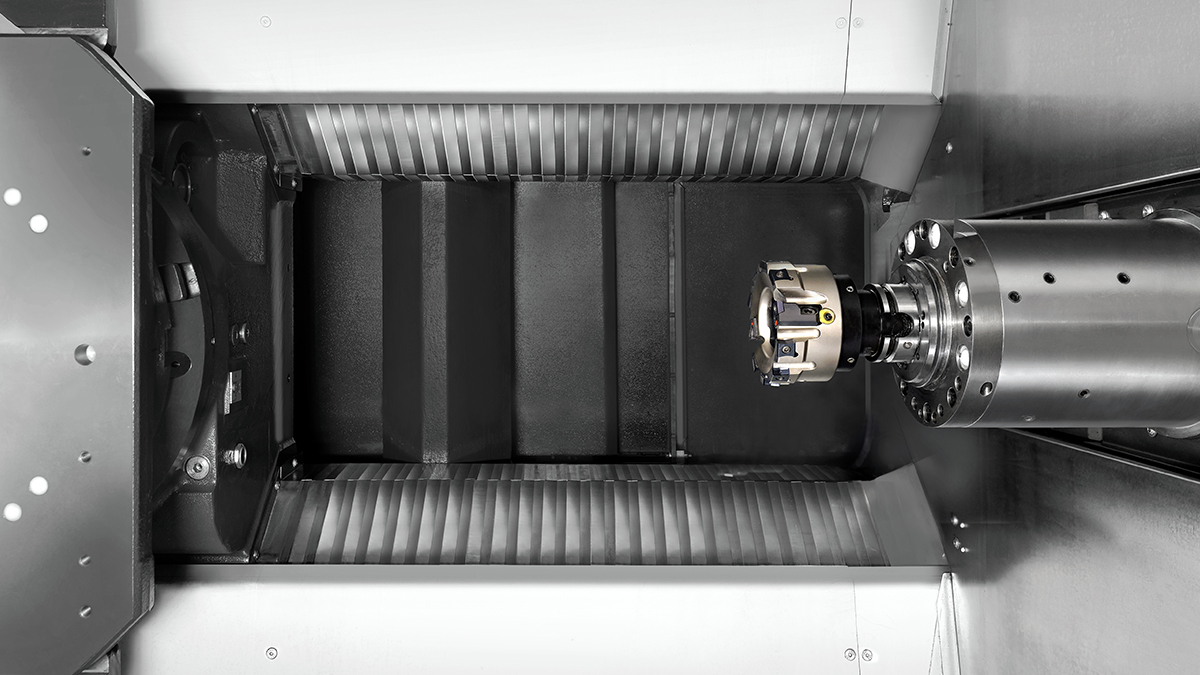

Rapid chip disposal

- H 2000 – H 6000: unrestricted chip fall below the spindle and rapid removal from the work area via central chip conveyor

- H 8000 – H 16000: chip disposal using spiral conveyors

- design: scraper or hinged belt conveyor (option), selectable according to application

- work area flushing and shower to support rapid chip evacuation on machines equipped with coolant units

- extraction unit (option) for removing coolant mist from the work area

- steep side panels and concertina covers with self-cleaning effect to prevent chip deposits

Siemens SINUMERIK ONE

- H 2000 – H 10000: Siemens SINUMERIK ONE

- main operating unit in console design, as standard on machine models H 2000 – H 10000*

- high-performance control for machining centres, meeting the highest standards of performance and machining precision

- optimally integrated and tailored to the requirements of HELLER machining centres

- digital drive technology and modern system architecture

- SINUMERIK Operate user interface for straightforward and intuitive machine operation

- HELLER Operation Interface for even greater ease of operation, as standard on machine models H 2000 – H 10000*

Fanuc 31i-B

- high-performance control for machining centres, meeting the highest standards of performance and machining precision

- operating elements optimally integrated into the machine’s main operating unit

- digital drive controller and modern system architecture

- iHMI operating software for machine models H 2000 – H 10000

- highest standards of precision and reliability

HELLER user interface with extended range of functions

- HELLER user interface with 4 function areas for more information at a glance

- 24” screen and multi-touch function, ideal for displaying documents and drawings

- practice-oriented Xtends: HELLER extensions with additional functions

- machine control panel with pushbuttons and 2 overrides for optimal control in all operating situations

- main operating unit designed as panel

- ergonomic operating panel at the tool setting station

- HT 2 or HT 10 handheld operating unit

- additional keyboard

- work area camera

- in-process tool monitoring (IPM)

- damage reduction

- tool requirements planning

- automatic loading/unloading sequence

- maintenance manager

- job management

- interpolation turning (IPT)

- PRODUCTION-Assist, QUALITY-Assist and SETUP-Assist

- HELLER Services Interface (HSI) and other HELLER4Industry products

- ASK.me AI chatbot

* As standard on machine models H 2000 – H 10000. Available as an option for H 14000 – H 16000.

Operation and maintenance

Working with HELLER H series machines, you can feel every day how much engineering experience has gone into these 4-axis machining centres. Whether at the workpiece setting station, during tool loading, programming or maintenance – your comfort, safety and above all, the productivity of your manufacturing operations always come first.

Maximum operating comfort during setting and production

- ergonomically arranged operating elements and control screens

- user-friendly control units with robust glass surface (touch)

- no plastic covers

- stainless steel elements at setting stations

- large safety window for an unrestricted view of the work area

- smooth-running work area door with linear guide opens the roof of the work area in the operator zone

- operating modes 2 and 3 included in the standard scope of supply

Options

- handheld operating unit

- screen blow-off for a clear view during machining with coolant

Setting and loading during machining thanks to the pallet changer

- large smooth-running doors for optimal access during loading and set-up using a crane or other handling equipment

- workpiece setting station, lockable at 90° indexing positions, with foot release, unlimited manual rotation

- easy-to-reach operating elements and media guns, integrated into the machine enclosure

Options

- automatically operated loading station door

- automatically rotating NC loading station

- software options: automatic loading and unloading sequence

Optimal accessibility for fast tool setting

- ergonomically arranged operating elements

- optimal-height insertion position with integrated release function for easy handling

- tool loading at the magazine while the spindle is running

Options

- ergonomic operating panel at the tool setting station

- tool loading during machining

- tool coding with RFID chip

- HELLER TRP (Tool Requirement Planning) for automatic generation of loading and unloading lists

Central supply area at the rear of the machine

- clear overview of all supply units with easy access

- smooth-running doors and easy-to-remove sheet metal panels

- easy and direct access to the control cabinet

- quick-response HELLER spare part service

Options

- maintenance manager for maintenance planning and operator assistance directly at the machine

- HELLER TPS (Total Productive Services): service agreements for inspection, maintenance and servicing

Automation solutions

In automated manufacturing and production centres, the primary focus is on reducing downtime and thus maximising system availability. HELLER has developed its own automation solutions that integrate seamlessly with its highly productive machining centres. To address the wide range of market requirements, this portfolio is complemented by specialised solutions offered by HELLER through best-in-class partnerships.

Pallet changer

First level of automation, integrated into the machine. Perfect for series production with medium to large batch sizes.

Linear pallet storage

Automatic handling of pallets for maximum flexibility. Perfect for series production with small to medium batch sizes.

Rotary pallet storage

Automatic handling of pallets for maximum flexibility in a minimum of space. Perfect for series production with small to medium batch sizes.

Options

Automation-READY

Cost-effective, subsequent integration into standardised pallet automation systems

IN-Automation

Optimised interface for fast, immediate integration into standardised pallet automation systems

Robots

Automatic loading and unloading of workpieces, fixtures and pallets, and automation of other handling operations. Perfect for series production with medium to large batch sizes.

Linear gantry

Linking of system components into production lines for maximum output. Perfect for high-volume production, delivering maximum output with minimal cycle times.

Mobile rack

Efficient loading of tool sets on rack-type magazines Portable cassette for tool storage, transport, loading and unloading. The mobile rack can be transported using an automated guided vehicle (AGV).

Background tool magazine

Central tool supply for multiple machines. Perfect for production systems with the highest levels of flexibility and automation.

Downloads

At a glance, our Download Centre offers an extensive range of information materials about our company, our products and services for you to download.

Ready4productivity

Stock machines at a special price

Are you looking for a machining centre, but have no time to put up with long delivery times? Then we have the perfect solution for you: discover the 4-axis and 5-axis machining centres from our H and HF series available at short notice. Pre-configured and available in various specifications – for maximum efficiency and diverse production requirements.

Ready4productivity

Stock machines at a special price

Are you looking for a machining centre, but have no time to put up with long delivery times? Then we have the perfect solution for you: discover the 4-axis and 5-axis machining centres from our H and HF series available at short notice. Pre-configured and available in various specifications – for maximum efficiency and diverse production requirements.

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!