HELLER solutions at Hansgrohe

High availability and flexibility

Hansgrohe SE ranks among the world's leading manufacturers of taps and showers worldwide. The company manufactures products characterized by quality, functionality, and design. Diversity in product design therefore calls for a high degree of flexibility. In 1995, the company made just 60 different versions at its factory in Schiltach. Today, there are 250 designs. To handle this variety, the company relies on 13 machining centres, 11 of which are from HELLER. The six H-series 4-axis machining centres are particularly impressive.

Task

- small batch sizes have to be realised at short notice through fast response times and high flexibility

- 250 versions of mixers with batch sizes of between 100 and 1,500 units

- design-oriented products present new challenges for machining complexity, contours change, components require contour cutting

- due to the broad product diversity, short setting times are also key

- process reliability is much more important than chip-to-chip times

Project scope & solution

- eleven machining centres, six of which are type H 2000

- 80 tool pockets in the standard version

- pallet changer for setting during the production process

Result

- compact 4-axis machining centres boast extremely stable and reliable axes

- over 90 percent availability

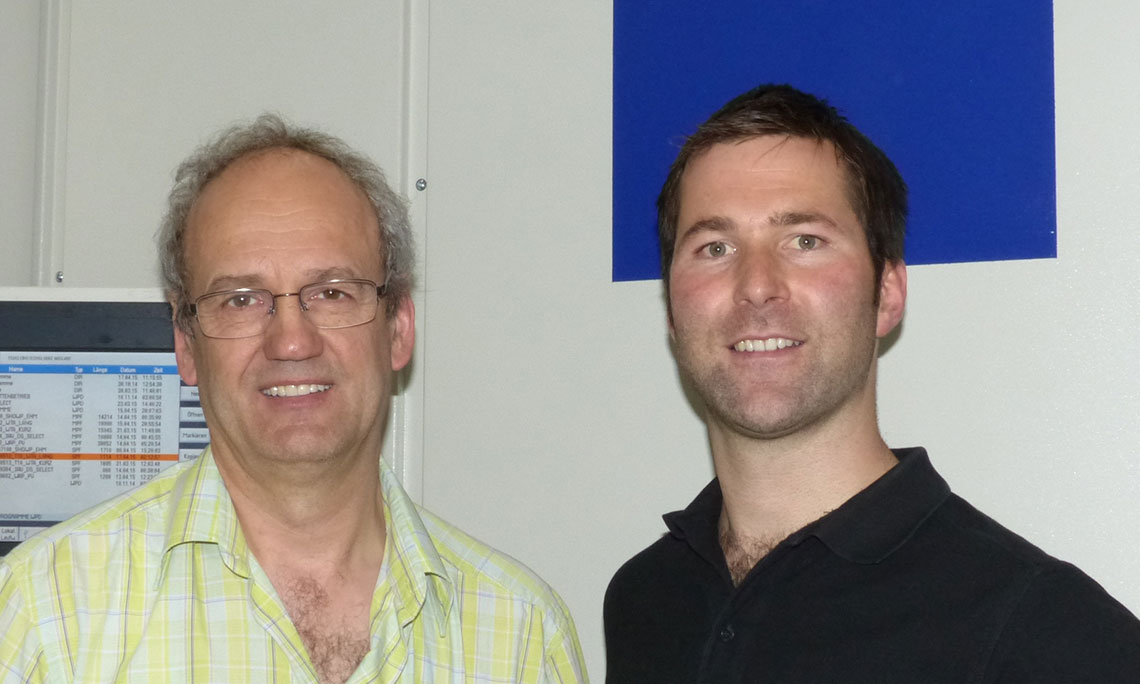

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!