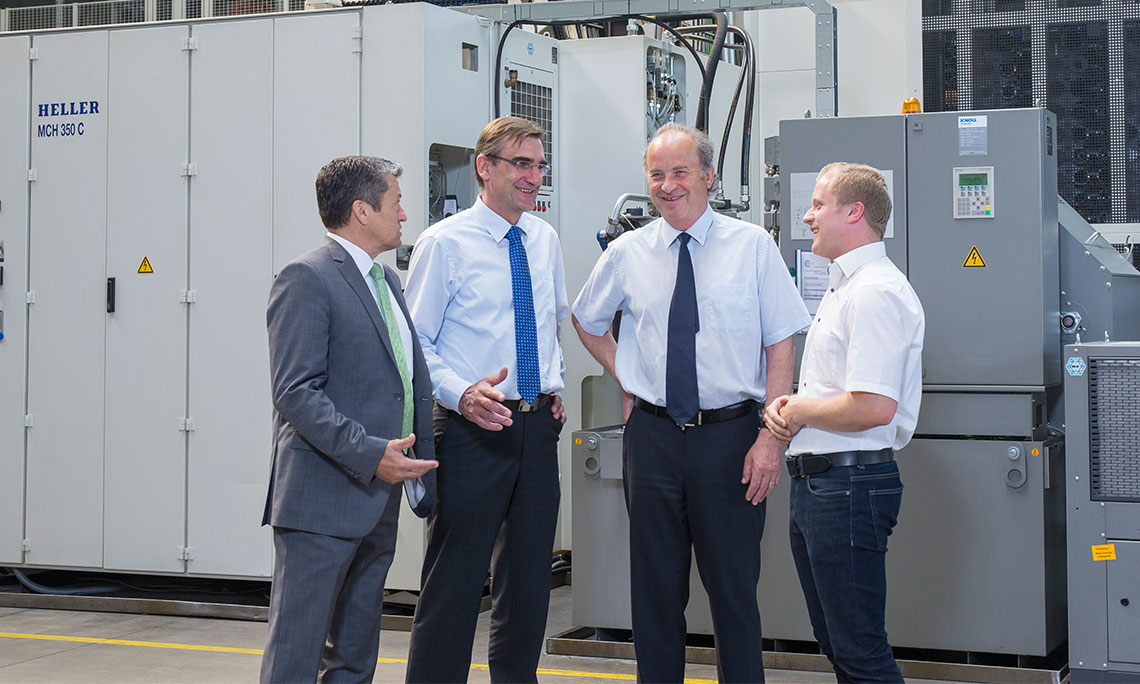

References

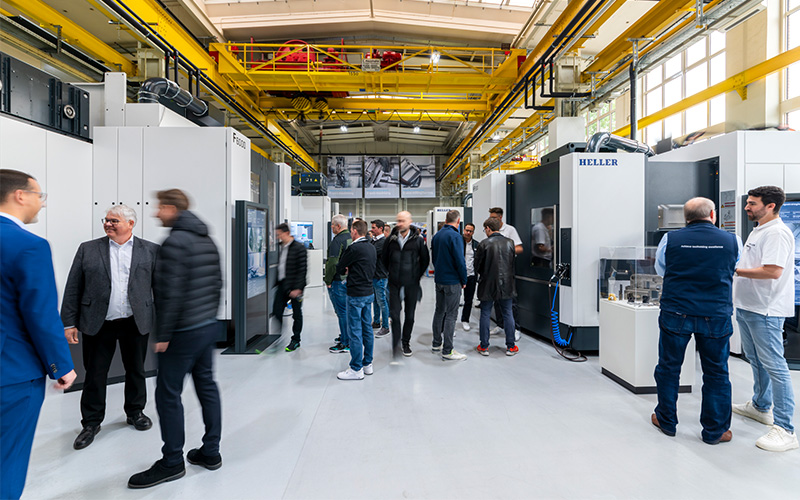

Convincing solutions for our customers

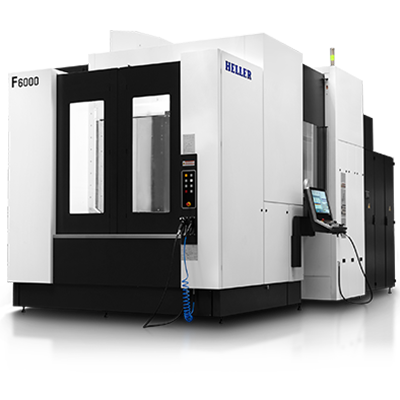

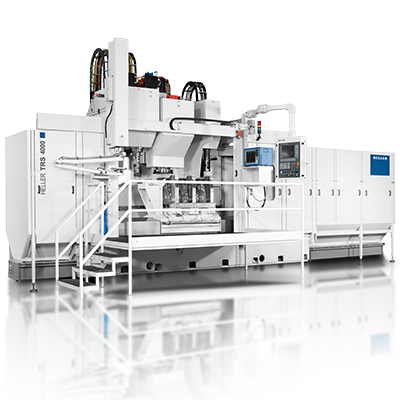

HELLER customers include companies from the automobile industry and their component suppliers, from general mechanical engineering, energy technology, fluid technology, aerospace and many other sectors.

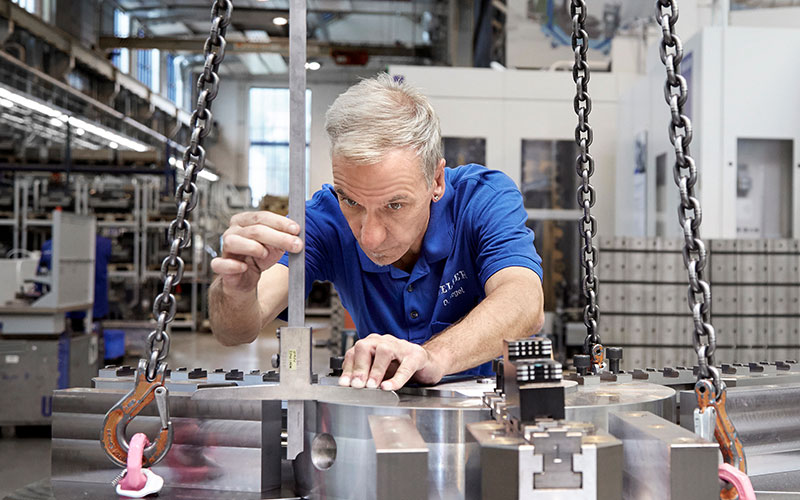

We offer complete solutions for workpiece-related tasks that provide convincing answers to our customers' requirements. Our solution capability comprises a broad range of parts and materials for the most diverse machining conditions - always supported by a comprehensive advisory and service offering.

See for yourself how HELLER solutions are successfully employed by some of our many reference customers.

Customer testimonials

Ready4productivity

Stock machines at a special price

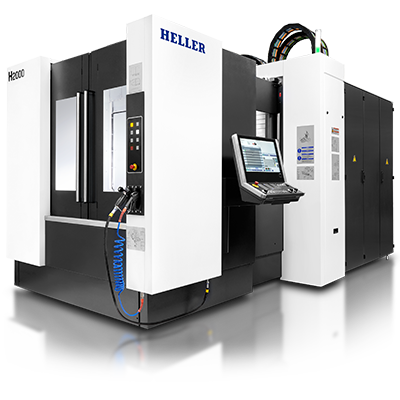

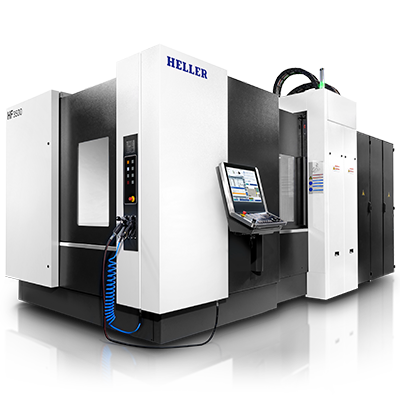

Are you looking for a machining centre, but have no time to put up with long delivery times? Then we have the perfect solution for you: discover the 4-axis and 5-axis machining centres from our H and HF series available at short notice. Pre-configured and available in various specifications – for maximum efficiency and diverse production requirements.

Ready4productivity

Stock machines at a special price

Are you looking for a machining centre, but have no time to put up with long delivery times? Then we have the perfect solution for you: discover the 4-axis and 5-axis machining centres from our H and HF series available at short notice. Pre-configured and available in various specifications – for maximum efficiency and diverse production requirements.

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!