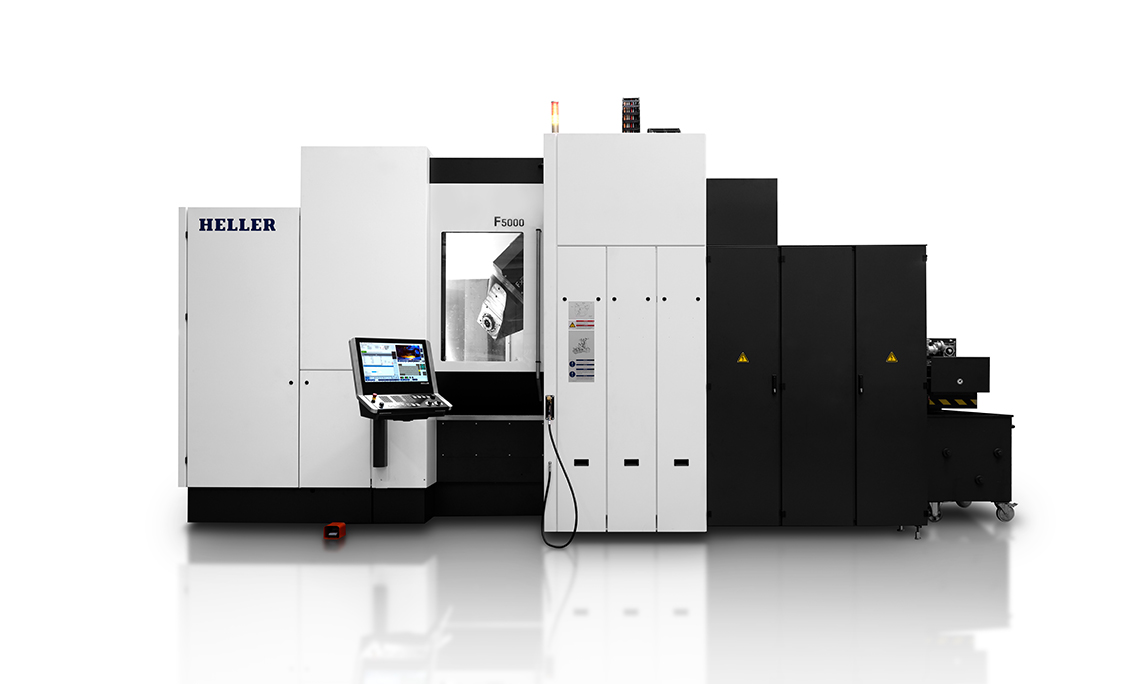

Machine concept

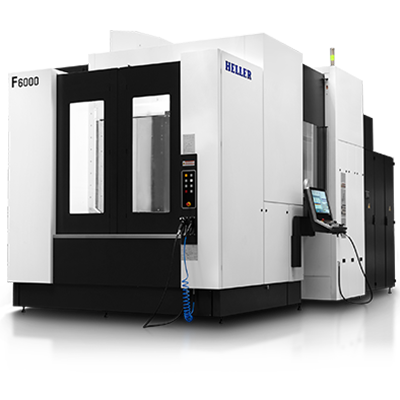

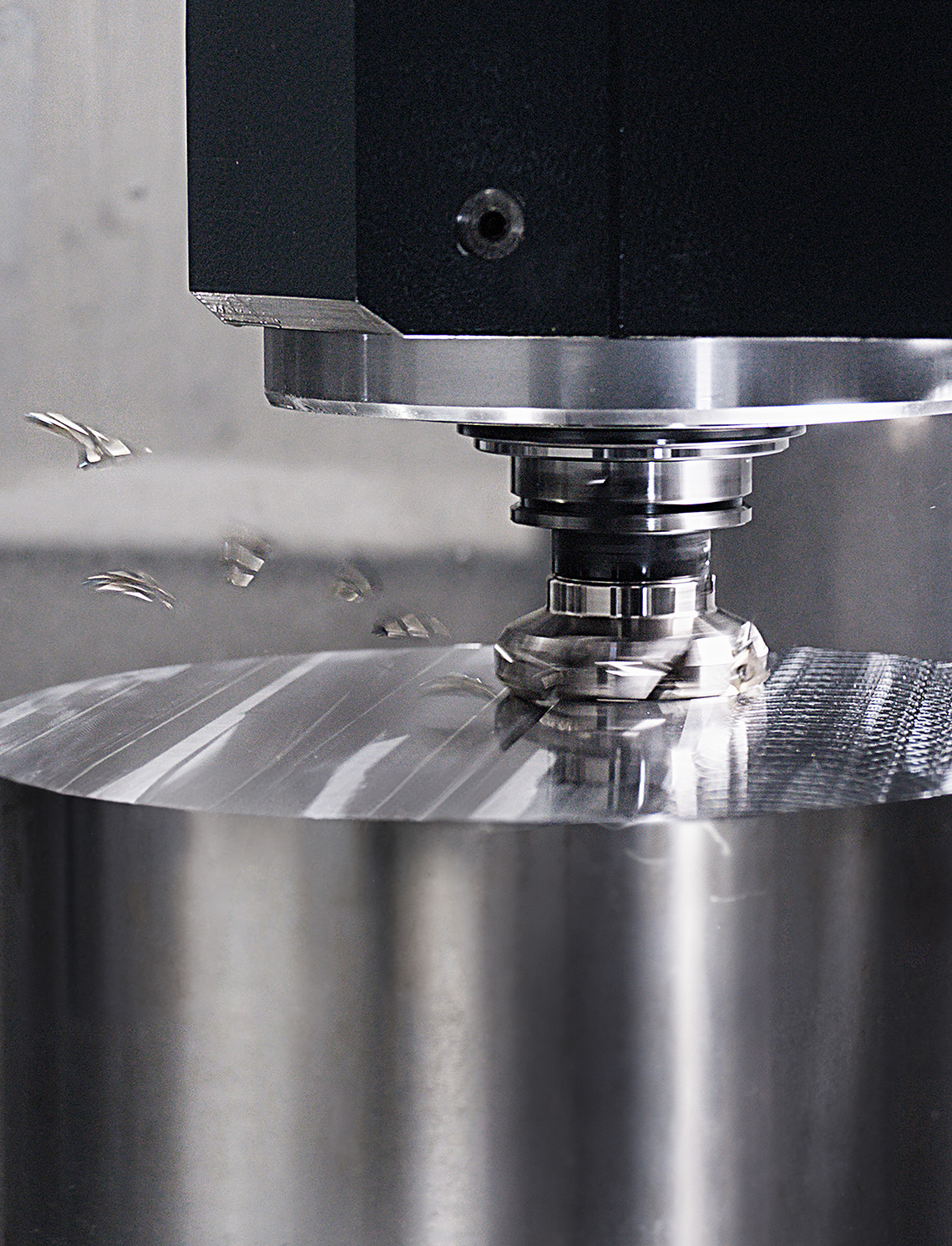

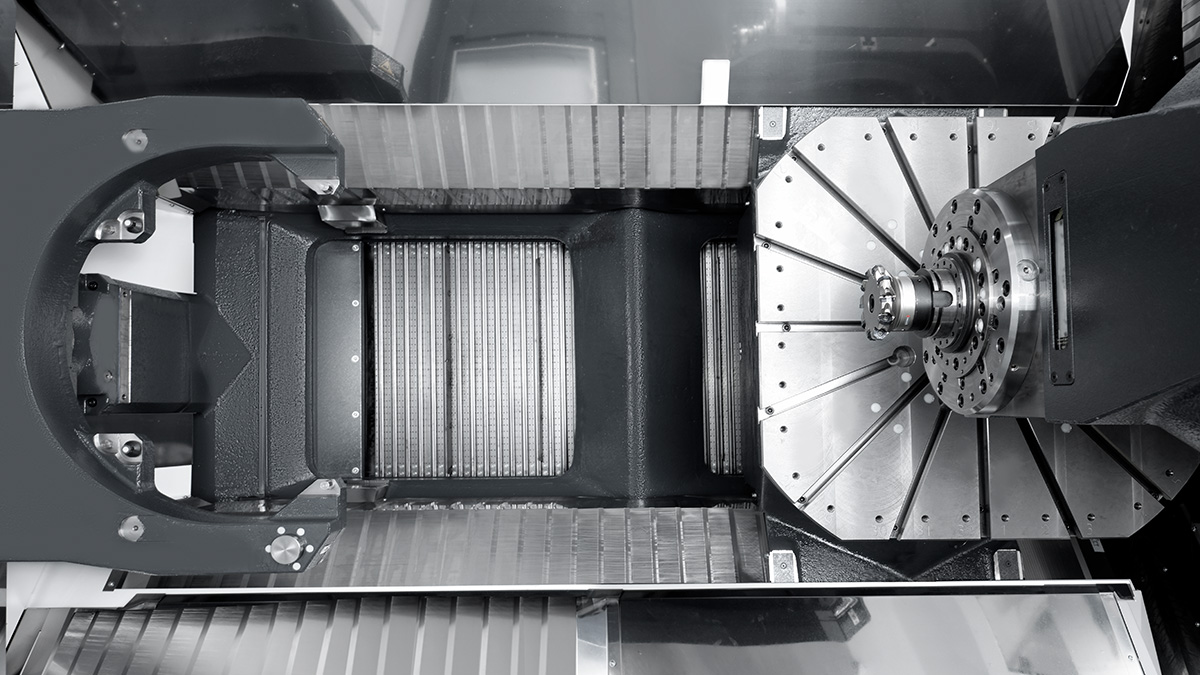

Only the perfect combination of rigidity and lightweight construction results in a machine design that ensures optimum surface finish and a long tool life. As with all HELLER machines, the main components of our new generation F series have been designed using FEM. The result is a machine bed optimised for rigidity and a mass-reduced column that ensure reliable productivity and high dynamics combined with perfect precision.

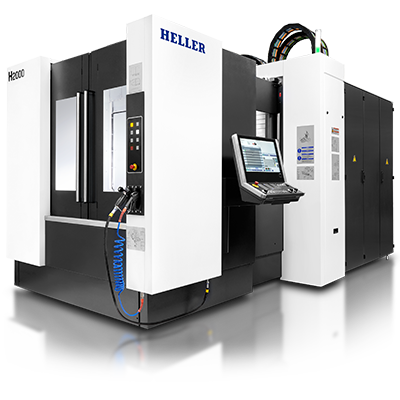

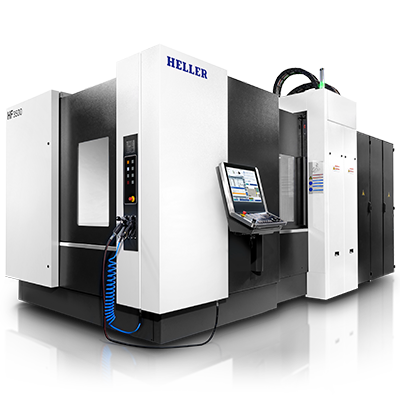

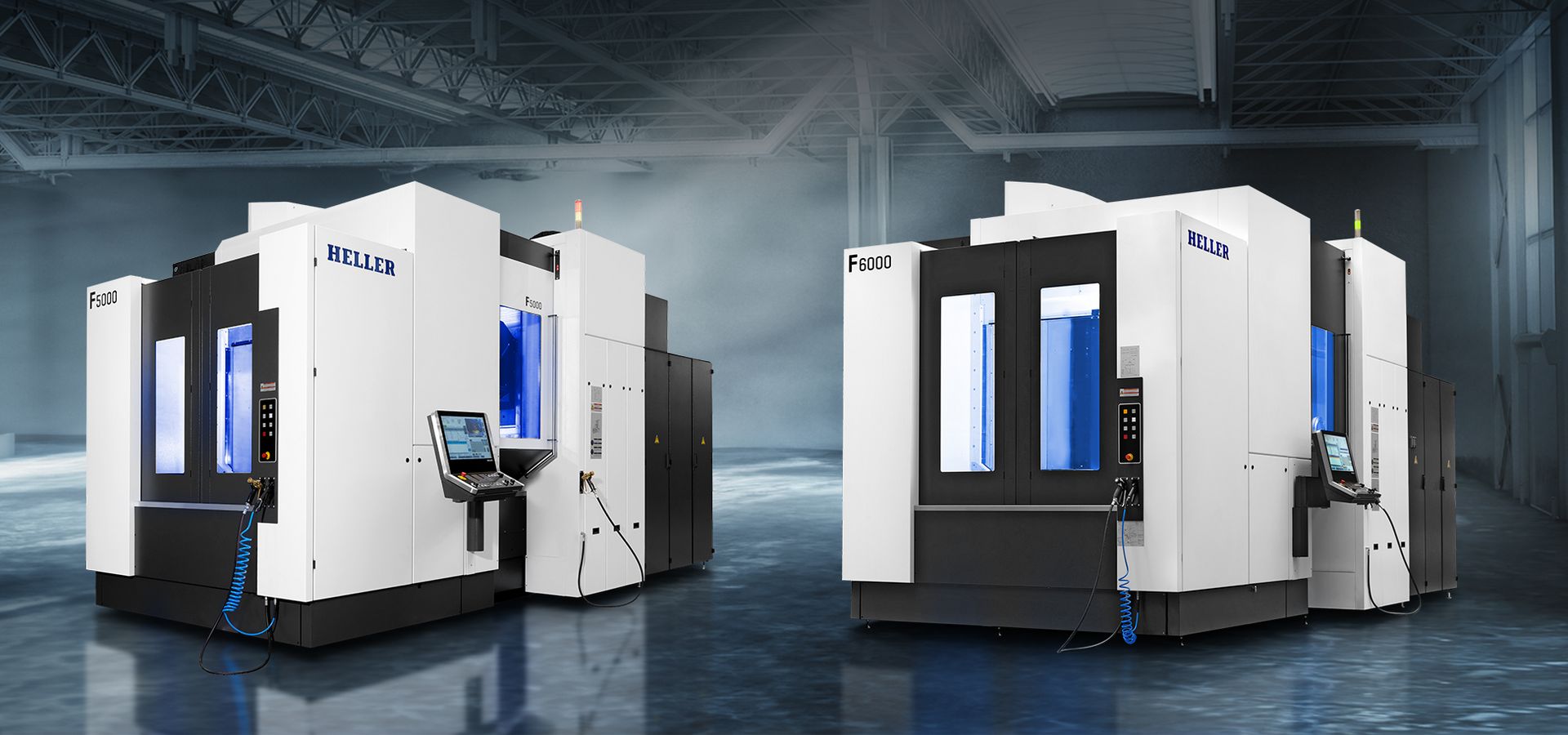

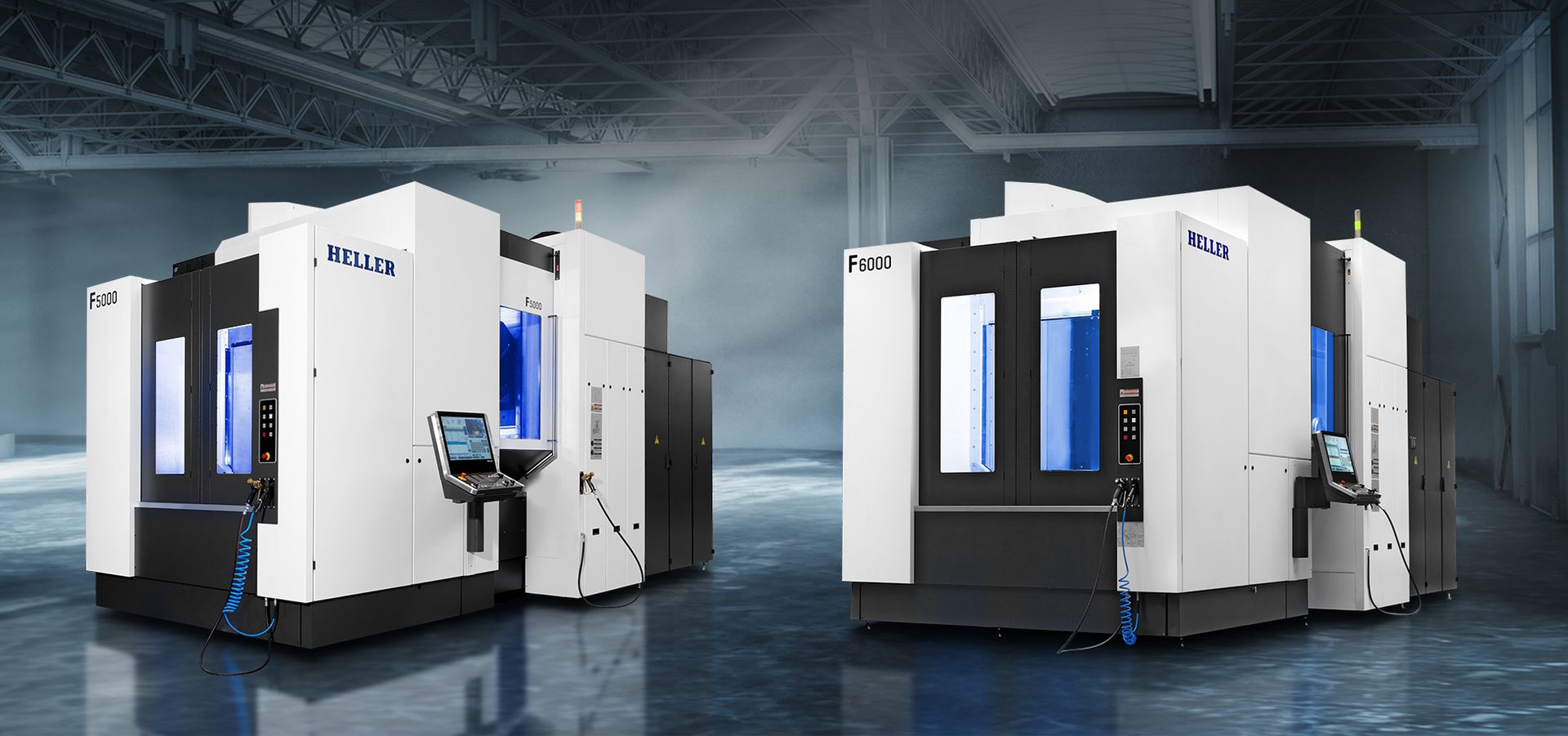

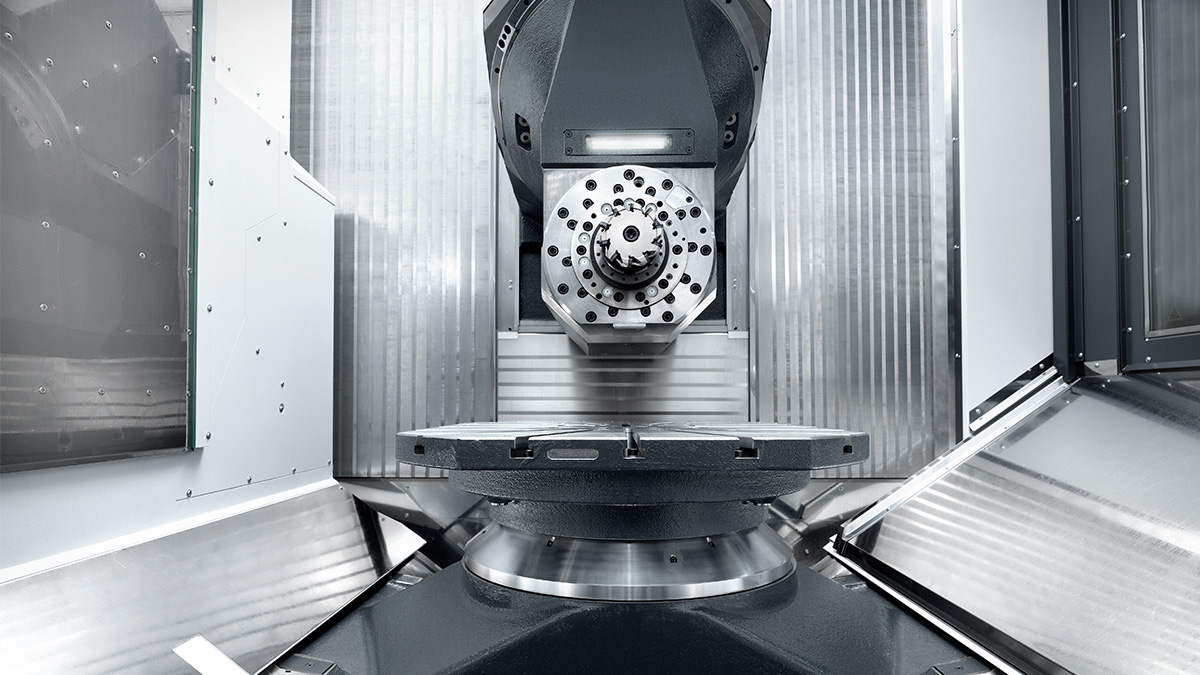

5-axis machining centres in horizontal orientation

- machine bed in cross-bed design for maximum rigidity even with high clamping loads

- traversing column in gantry-design for fast positioning and short idle times

- cast iron structural components with topology optimised

- design for maximum stability and damping in the force flow

- pallet changer with lift-swivel principle, designed as a fork-type changer for high clamping load and short pallet change time

- chain-type or rack-type tool magazines combined with fast NC tool changer for shortest tool provisioning times

Robust 5-axis kinematics with 5th axis provided by the tool

- machine bed supporting the X and Z axes in cross bed design

- machine column moves in X-direction and supports the machining unit

- machining unit moves in Y-direction, compact and robustly integrated into the machine column

- rotary table (B-axis) moves in Z-direction and rotates the workpiece continuously (360,000 x 0.001°)

- 5th axis designed as swivel head (C-axis) for continuous motion (350,000 x 0.001°)

Maximum performance with lasting precision

- linear axes with wide roller guides driven by precision ball screws with cooled drives or drive flanges

- Z-axis with drive on both sides for fast feed motions and free chip fall under the spindle

- direct, absolute measuring systems with low positional tolerance for maximum precision

- rotary axes with large YRT bearing and automatic clamping for maximum stability and high tangential moments

- rotary table with duplex worm gear for maximum performance in 5-axis machining

- direct driven high-speed rotary table for mill-turn applications (optional)

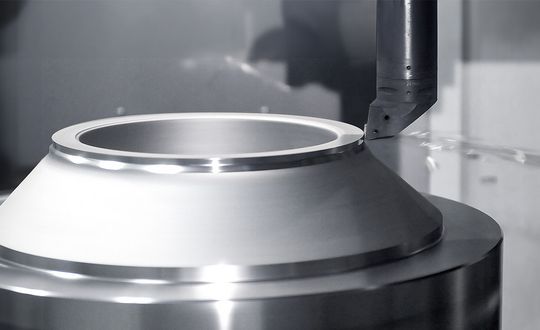

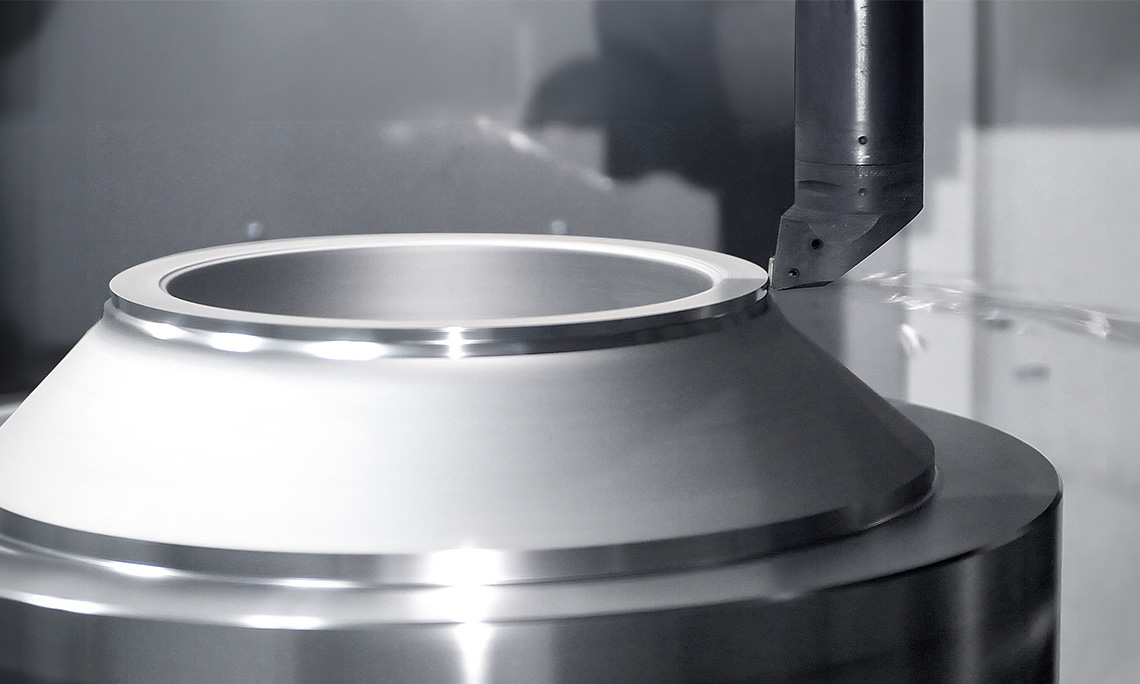

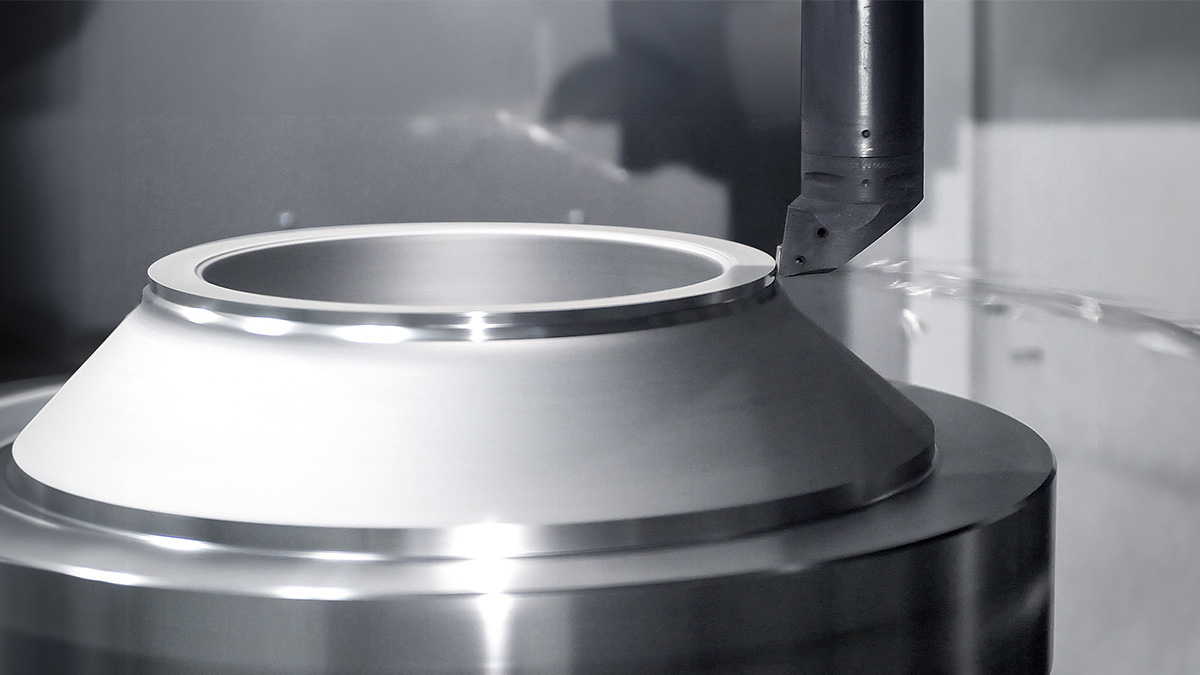

Mill-Turn

The optional Mill-Turn functionality enables combined milling and turning on a single machine – giving you even greater flexibility for the machining of your workpieces. Machining in a single set-up provides maximum component accuracy, while the use of a high-torque rotary table ensures maximum productivity.

Combined technologies milling and turning on a single machine

- NC rotary table in DDT (Direct Drive Turning) design

- HSK-T tool holder for optimum turning accuracy

- spindle locking for secure hold of the turning tools

- balancing technology cycle for balancing of the workpieces and fixture in the machine

- Siemens NC turning cycles for easy programming of turning operations

NC rotary feed table with rotary function

- direct drive rotary table for high speeds in turning operation and high milling dynamics

- permanent cooling for optimum accuracy at high speeds

- large YRT bearing for maximum stability and high tilting moments

- hydraulic clamping with integrated automatic clamping for maximum tangential moments

- integrated media interface for hydraulic workpiece clamping (80 bar, optional)

- media interface in Mill-Turn version for hydraulically operated universal power chucks

- tool measurement with precision laser and probe for turning tools

- oscillating speed: technology cycle to eliminate vibration in critical processes

- ChipBreak: technology cycle to prevent long chips and thread chips

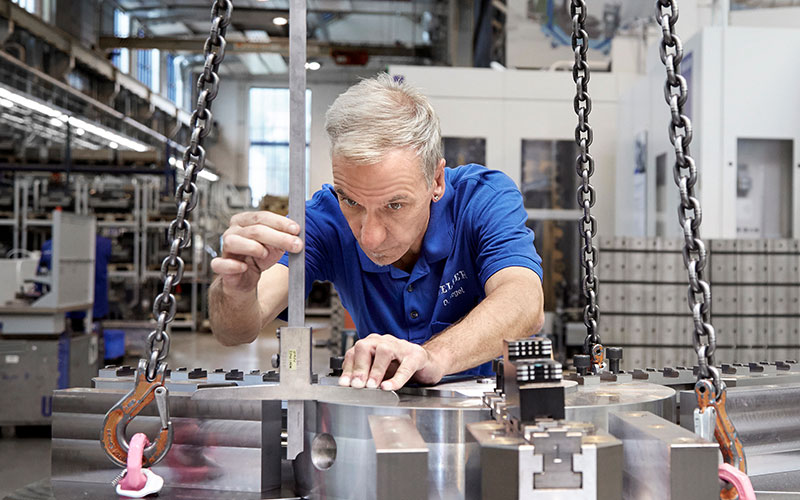

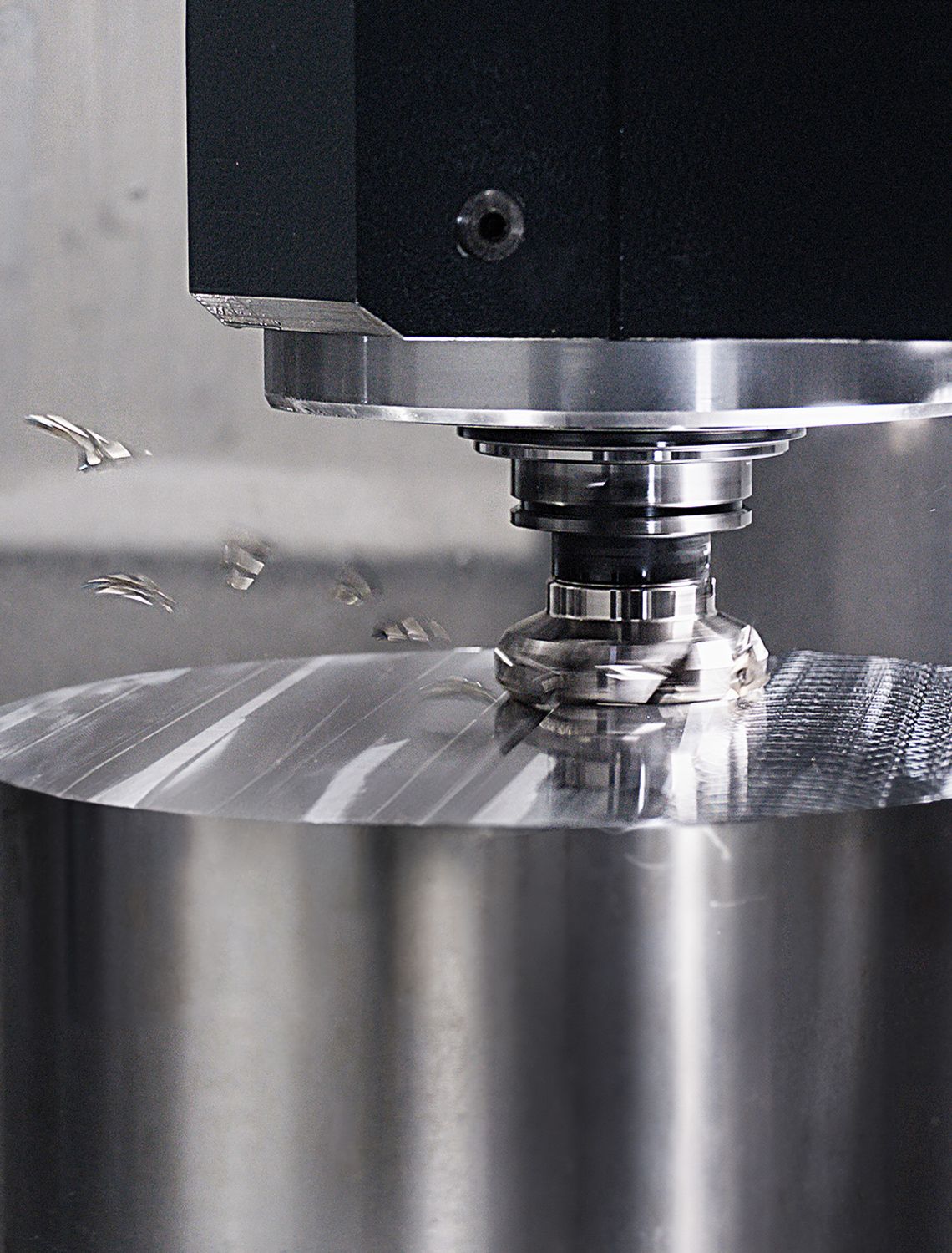

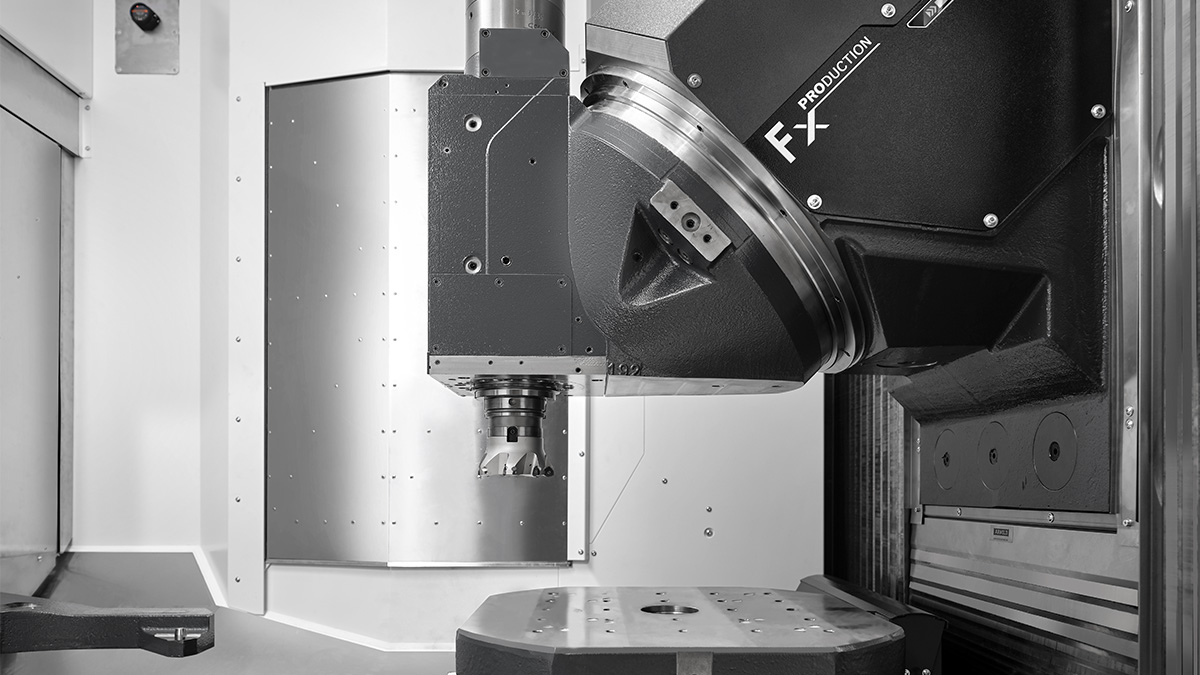

Machining units

Optimum process stability in 5-axis machining is also a question of having the right spindle. With our new generation F series you can choose from a range of swivel head designs. Whether it is heavy-duty cutting of cast iron or steel, high-volume machining of light metals or vertical, horizontal and tilted turning with the optional Mill-Turn functionality – we have the right solution to suit your requirements.

Broad range of powerful machining units

- machining units with 5th axis provided by the tool with robust swivel head kinematics

- 4 high-speed motor spindles for universal use

- 1 gear unit providing maximum torque, perfect for machining difficult-to-machine materials

- HSK-A 100 tool shank as standard for machining units with motor and gear-driven spindles (HSK-A 63 optional)

- thermal stability and precision through permanent cooling, precision cooling unit and thermal growth compensation of the spindle

- automatic clamping of the 5th axis, optional hydraulic clamping for maximum stability in heavy-duty machining with tilted rotary axes

- sturdy cast iron guide slide with high dynamic rigidity and damping

Highest performance during machining

- high projection length in vertical position for precise machining behind the rotary centre of the rotary table

- compact design and high rigidity thanks to the robust 45° swivel head kinematics and short distance between bearing and tool shank

- dynamic, backlash-free swivel drive with electrically pre-loaded motors

- large C swivelling range of 350° for high flexibility in 5-sided machining

- integrated LED light (WorkLIGHT) as standard and remaining path display as part of the optional SETUP-Assist function

Top equipment and features

SETUP-Assist

- assistance system that actively supports the operator when running in processes

- remaining path display integrated into the machining units

- collision monitoring between machine components and tools

- utilisation display for linear axes, rotary table and spindle

HELLER attachment head support (MSK)

- precondition for the use of attachment heads (e.g. angular heads)

- enlarged support basis with three-point rest

- integrated torque input and media transfer

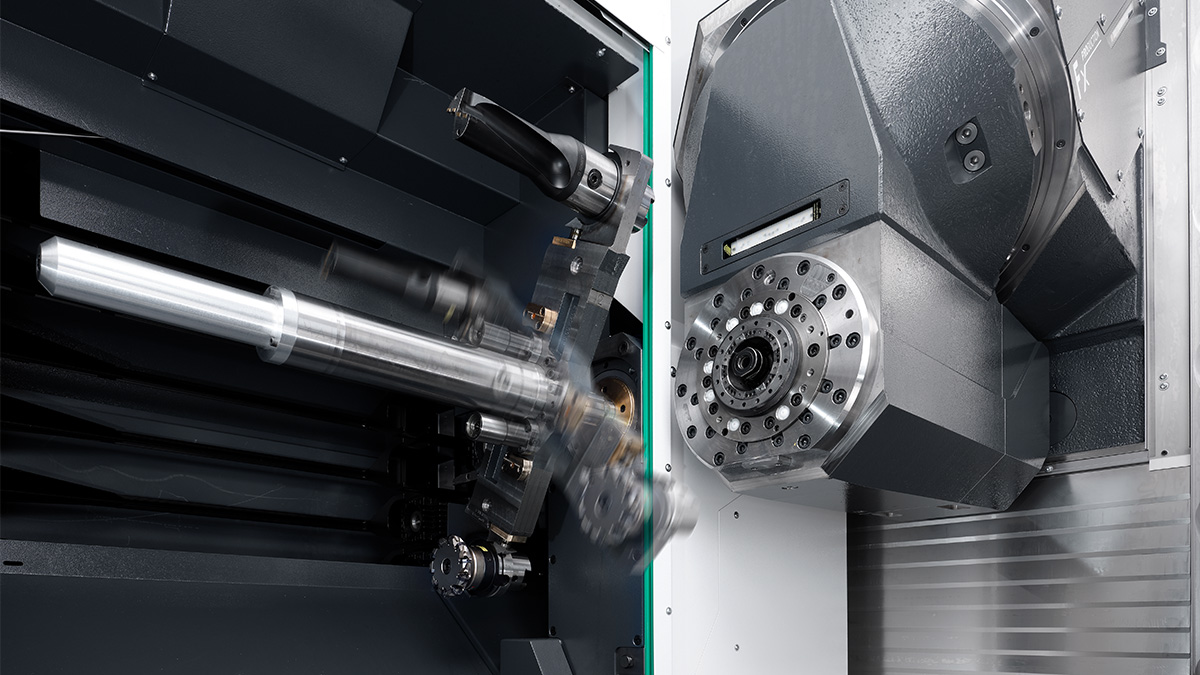

Tool management

Particularly in 5-axis and mill-turn machining, you work with a wide variety of tools and large tool geometries on a daily basis. No problem for our machining machining centres: they allow you to continue to use your tooling flexibly, while ensuring short tool loading times, short downtimes and short non-productive times.

Fast tool provisioning

- 3 chain-type magazines with up to 150 positions

- double chain with high traversing dynamics and sturdy tool holders mounted on both sides

- short tool-to-tool times due to tool provisioning parallel to machining

- tool shank in enclosed holders: protection against contamination and optimum hold during positioning

- tool loading station with optimum accessibility for fast and ergonomic tool loading

High storage capacity

- 1 rack-type magazine with 489 positions for machines with HSK-A 63

- 4 rack-type magazines with up to 425 positions for machines with HSK-A 100

- fast tool handling with highly dynamic tool loader

- integrated rotary station for loading of multiple tools parallel to machining

Short chip-to-chip times thanks to fast tool change

- two NC axes with lift/swivel principle for high dynamics and long-term precision

- sturdy double gripper for a secure hold with heavy tool weights and moments of weight

- integrated tool provisioning place for supply of the next tool during machining and short tool-to-tool times

- rapid tool breakage detection (SBBK) enables shank tools to be checked for breakage parallel to machining (optional)

Operating convenience and productivity

- tool loading during machining (HZPR) without affecting the ongoing machining process

- cleaning of tool shanks and pockets at the tool provisioning position of the chain-type magazines

- tool coding for automatic storage and transfer of tool data in the tool

- precision laser measurement and checking of the tools in the spindle

Workpiece management

Whether with pallet changer (APC) for flexible series production or in the FLEX version with an interchangeable pallet for maximum flexibility in terms of workpiece dimensions: the new generation of the F series comes perfectly prepared for both concepts and offers you reliable workpiece management. On top of that, the machines can easily be integrated into standard automation systems.

Machine with pallet changer as the ideal solution for series production

- automatic pallet changer with lift/swivel principle

- high maximum clamping load with robust, hydraulic drive

- optimum application of force to machine pallets due to the fork shape of the lift-and-swivel bridge

- consistently high tool change accuracy due to robust alignment elements and extensive blow-off of functional surfaces

- hydraulic pallet clamping for secure hold, even under high process forces

- machine pallets with DIN hole pattern and standardised alignment elements for rapid mounting of clamping fixtures

- increased clamping load for even more flexibility in production (optional)

Machine without pallet changer for maximum flexibility

- large workpiece diameter without restrictions due to pallet changer

- increased load as standard

- reduced machine length

- interchangeable pallet as standard for quick setup outside the machine

- ‘IN-Automation’ version with optimized design for the integration into pallet automation

Rotary feed table with duplex worm gear

- high damping for heavy-duty machining

- direct, absolute measuring system for maximum positioning accuracy

- hydraulically operated rotary table clamping with automatic clamping for maximum stability when machining with tilted rotary axes

- pallet mounting with diamond-type dowel pin and indexing pin for maximum pallet change accuracy

- integrated swivel clamps with high clamping force

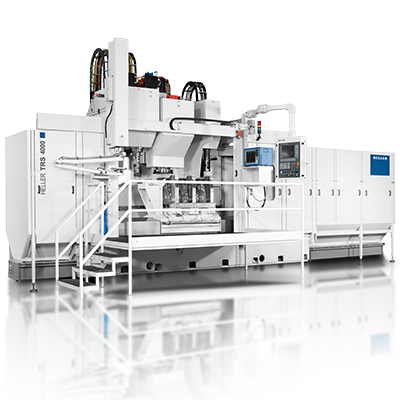

Storage of machine pallets and automated setting of one or multiple machines

- standardised linear storage systems with up to 15 storage locations depending on type and size (optional)

- everything from a single source: complete solutions for fast installation and commissioning

- specific advantages with a large part mix and flexible series production with small batch sizes

- optimal capacity utilisation with continuous pallet feed to one or multiple machines

- high cost efficiency of the systems and maximum flexibility in production

Options

- ‘IN-Automation’version with optimised interface for fast, immediate integration into standardised pallet automation systems

- ‘Automation-READY’ version for cost-effective, subsequent integration into standardised pallet automation systems

- standardised host computer interface for optimal connection to a host computer

- high number of functions and options for automated production control

- media interface for hydraulic workpiece clamping

Supply and disposal

Fast and effective chip removal is a top priority with our machining centres. The design of the work area prevents the accumulation of chips and ensures that they are quickly removed from the machine. You can select the most suitable conveyor design and coolant unit for your individual work processes. Precision and process are assured!

Media supply area on the rear of the machine

- easy maintenance with optimum accessibility, all supply units at a glance

- central oil-air lubrication for key components

- sealing air and selective blow-off of interfaces for continuous, smooth machine operation

- media interface for hydraulic workpiece clamping with 80 bar, 200 bar or 250 bar (optional)

- compressed air and water guns integrated into the machine housing at the workpiece loading station and operating station

Effective cooling lubricant supply and filtration

- coolant units: paper band filter or backflush filter with high tank volumes available as options

- internal coolant supply (IKZ) through the tool with high pressure 50 bar (optional: 70 bar)

- internal coolant supply with up to 7 pressure steps freely programmable via NC program

- external tool cooling (AKZ) with flushing nozzles (optional) integrated into the spindle

- integrated work area shower with adjustable nozzles for optimum flushing of the work area and cooling of the workpiece

Options

- coolant cooler

- coolant temperature control unit for high thermal stability and precision

- automatic filling of the coolant unit

- oil skimmer for separation of foreign oil from the cooling lubricant tank

- automatic setting station flushing

Rapid chip disposal

- free chip fall below the spindle and quick removal from the work area

- central chip conveyor for fast disposal of chips to the rear of the machine

- chip conveyor either as scraper belt or hinged conveyor, depending on the application (optional)

- steep stainless steel side panels and slat coverings with self-cleaning effect to prevent chip deposits

- integrated work area shower to support rapid chip removal

- extraction unit for the removal of coolant mist from the work area (operating principle: mechanical air filter) (optional)

Control technology

In everyday working life, speed is of the essence. The modern, high-performance Siemens SINUMERIK ONE control with HELLER Operation Interface makes things easy for you and provides perfect support for your tasks: with intuitive operation, easy programming, cycle support and key information always at your fingertips.

Latest generation control system for maximum performance

- high-performance control Siemens SINUMERIK ONE to meet the highest standards of performance and machining precision

- console-design main operating unit and ergonomic control panels around the machine

- digital drive technology and modern system architecture

- Profinet bus system for ultra-fast real-time communication

- IO link system for direct diagnostics and parametrisation of sensors

Options

- panel-design main operating unit (ITC 2400)

- convenient operating panel at the tool loading station

- HT 2 or HT 10 handheld operating unit

- additional keyboard

- work area camera

User interface with extended range of functions

- HELLER user interface with 4 function areas for more information at a glance

- practical HELLER applications (Xtends) with useful additional functions

- 24” screen and multi-touch function, ideal for viewing documents and drawings

- machine control panel with pushbuttons and 3 overrides for optimum control in all operating situations

- third override reduces rapid traverse, helping to eliminate the risk of a collision during manual operation

Options

- in-process monitoring (IPM)

- damage reduction

- tool requirements planning

- automatic loading/unloading sequence

- maintenance manager

- job management

- interpolation turning (IPT)

- SETUP-Assist (process setup wizard)

- HELLER Services Interface (HSI) and other HELLER4Industry products

Operation

Working with HELLER machines, you can feel every day how much engineering experience has gone into these machining centres. Whether at the workpiece setting station, during tool loading, programming or maintenance – your comfort, safety and, above all, the productivity of your manufacturing operations are always in the foreground.

- ergonomically arranged operating elements and control screens

- swivelling main operating unit with clamping function integrated into the machine enclosure to save space

- good view into the work area thanks to large safety window

- smooth-running, linear-guided work area door opens the work area roof in the operating area

- operating modes 2 and 3 included in the standard scope of supply

Options

- HT 2 or HT 10 handheld operating unit

- screen blow-off system or Roto Clear for a clear view during wet machining

- large smooth-running doors for optimum access during loading and set-up using a crane or other handling equipment

- workpiece setting station lockable in 90° indexing positions

- easy-to-reach operating elements and media guns

Options

- automatically operated setting station door

- automatically rotating setting NC setting station

- software options: automatic loading and unloading sequence

- elevated position of operating units and media access at the operating station and workpiece setting station

- ergonomically arranged operating elements

- optimum-height insertion position with integrated unclamping function for easy handling

- tool loading at the magazine while the spindle is running

Options

- convenient operating panel at the tool loading station

- tool loading during machining

- tool coding with RFID chip

- HELLER TRP (Tool Requirement Planning) for automatic generation of loading and unloading lists

Technical data

| Product selection | F 5000 | F 6000 | |||||

|

Positioning range

X/Y/Z | mm | 800/8501)/1,100 | 1,000/1,000/1,400 | ||||

|

Rapid traverse speed

X/Y/Z | m/min | 65 | 65 | ||||

|

Acceleration

X/Y/Z | m/s² | 6/71)/7 | 6/71)/7 | ||||

|

Positioning tolerance Tp / At2) X/Y/Z | VDI/DGQ 3441 / ISO 230 | mm | 0.005 | 0.005 | ||||

|

Tool shank

SK/BT available as an alternative for PCUe | Mill-Turn: HSK-T | Size | (HSK-A 63) | HSK-A 100 | (HSK-A 63) | HSK-A 100 | ||

|

Chip-to-chip time

t₂,₃ | VDI 2852 | s | (3.9) | 4.0 | (4.1) | 4.2 | ||

|

Clamping surface

Nominal size | mm | 630 x 630 | 630 x 630 | 630 x 630 (800 x 800) | 630 x 630 (800 x 800) | ||

|

Workpiece dimension

Diameter x height | mm | Ø 1,100 x 1,100 | Ø 1,100 x 1,100 | Ø 1,300 x 1,3003) | Ø 1,300 x 1,3003) | ||

| Clamping load | kg | 1,500 (2,000) | 1,500 (2,000) | 1,500 (2,000) | 1,500 (2,000) | ||

| Machine control | Siemens SINUMERIK ONE | Siemens SINUMERIK ONE | |||||

( ) = optional values

- = not available

1) DCU/SCU

2) position uncertainty

3) consider limitations

Downloads

At a glance, our Download Centre offers an extensive range of information materials about our company, our products and services for you to download.

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!