HELLER machines & solutions

More than just machine tools

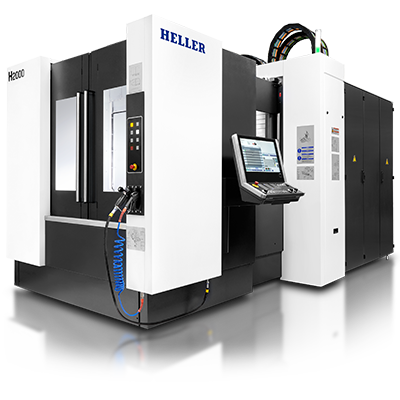

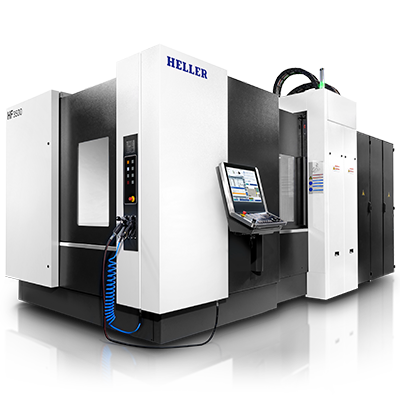

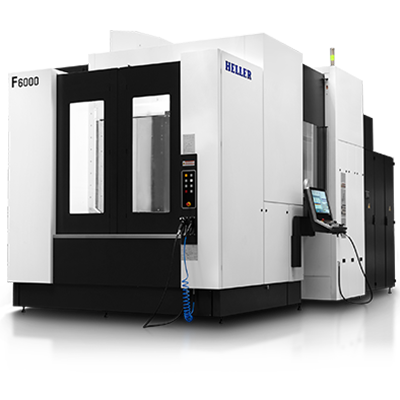

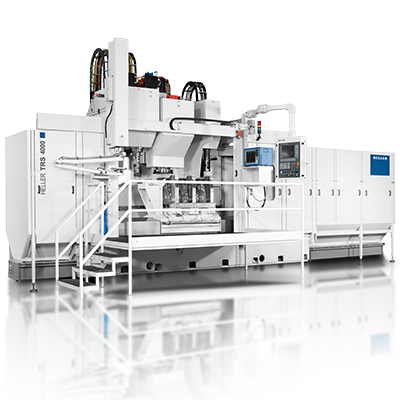

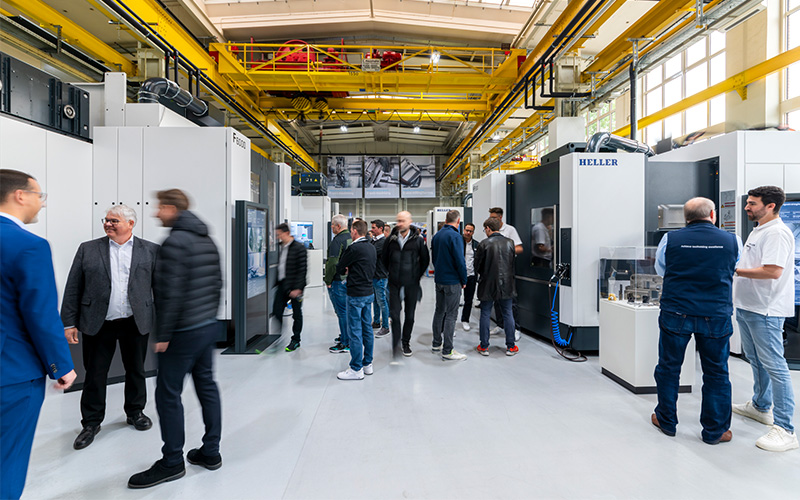

HELLER is synonymous with state-of-the-art CNC machine tools and manufacturing systems for metal-cutting machining. The broad HELLER product range comprises 4- and 5-axis machining centres, milling/turning machining centres, custom machines and process machines, coating modules, as well as machines for crankshaft and camshaft machining.

With HELLER4Industry and HELLER4Use, we offer our customers an extended range of solutions to achieve increased productivity and flexibility in production.

From this range, HELLER generates customer-oriented complete solutions – from the stand-alone machine to the fully-automated turnkey production system.

HELLER CNC machine tools

Productivity over the full spectrum

Machine finder

Ready2deliver – Ready4productivity

The quick way to boost your productivity

Are you looking for a machining centre, but have no time to put up with long delivery times? Then we have the perfect solution for you: discover the 4-axis and 5-axis machining centres from our H and HF series available at short notice. Pre-configured and available in various specifications – for maximum efficiency and diverse production requirements.

Ready2deliver – Ready4productivity

The quick way to boost your productivity

Are you looking for a machining centre, but have no time to put up with long delivery times? Then we have the perfect solution for you: discover the 4-axis and 5-axis machining centres from our H and HF series available at short notice. Pre-configured and available in various specifications – for maximum efficiency and diverse production requirements.

The benefits of HELLER

This makes our machines

Made by HELLER

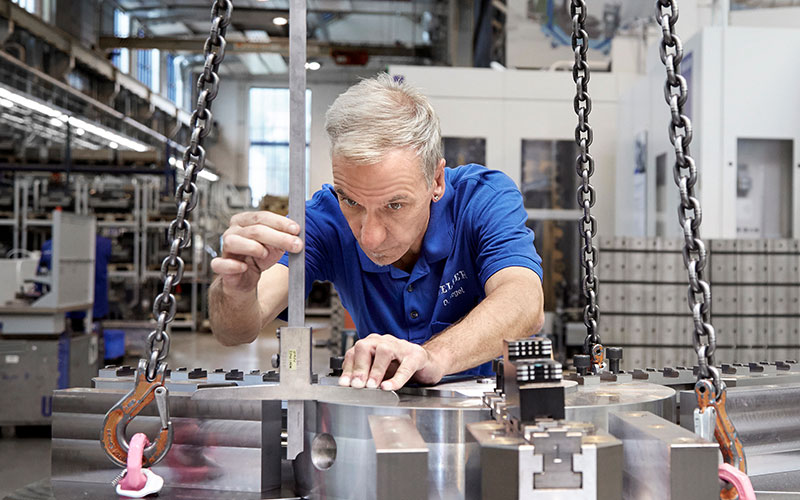

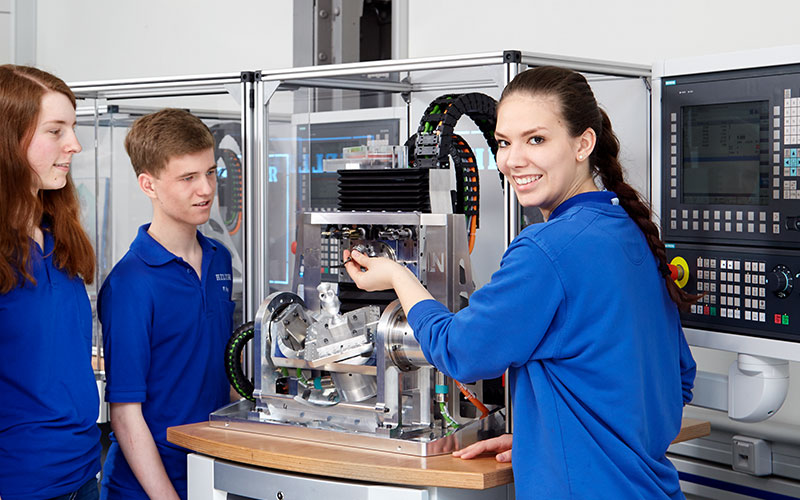

HELLER machines produce HELLER machines

The basis for quality and precision for each HELLER machine is a simple principle: HELLER machines produce HELLER machines. Our machine tools are manufactured within a global production network operating to the same high HELLER quality standards everywhere. We develop and produce ourselves all components that ensure the reliability, accuracy and quality of a HELLER machine. Especially when it comes to the daily availability of your machine, we consider the deepest vertical integration as paramount. Therefore: Made by HELLER – a quality seal on which you can rely.

Made to Work

Stable processes for your daily production routine

The challenges you face in production are increasingly smaller batch sizes, shorter lead times and growing component complexity. What you need is high process dependability and stability in production – around the clock and with minimal per-piece costs. HELLER machine tools are designed for stable processes in harsh daily production environments and guarantee constant maintenance of your production facility. Tried and proven components, adjusted speeds and solid basic equipment ensure robust machines that can be fully utilised, even to their limits, 24/7 in a 3-shift operation: Made to Work

HELLER4Industry

Fit for Industry 4.0: Increasing machine productivity through digitisation

Against the backdrop of Industry 4.0 and digitisation, we developed HELLER4Industry, an innovative concept that further increases the productivity of HELLER machining centres, thereby generating added value for customers.

HELLER4Use

The new usage model for added flexibility in your production facility

Our innovative Pay-per-Use model HELLER4Use allows you to adapt the capacities of the HELLER machining centres to suit your current order situation. This means incredible flexibility for your production facility – without any capital tie-up or initial investment, while HELLER safeguards machine availability. How is it done?

HELLER industry solutions

Tailored for your requirements

Our customers include companies from the automobile industry and their suppliers, from general mechanical engineering, energy technology, fluid technology and many other sectors. A solution that suits your industry and your requirements? HELLER has one. See for yourself.

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!