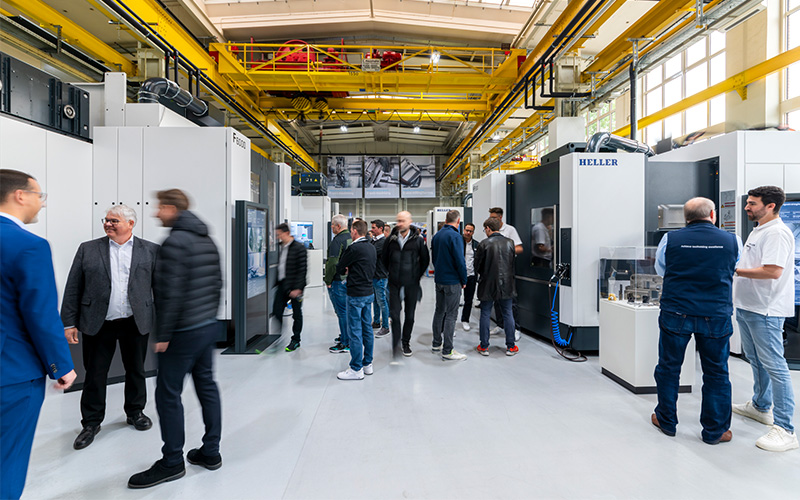

Keep pace with the best

Modernisation without new acquisition – HELLER Retrofit keeps existing machines like new. Reuse of the existing infrastructure and peripheral units make retrofits an economical alternative. Individually adapted to suit your requirements, our specialists overhaul the existing system and achieve improvements in terms of productivity and precision. As well as using HELLER genuine spare parts, we also offer you comprehensive quality assurance and guarantees across the entire range of services.

The benefits to you

- functional safety for machines: mandatory in Europe

- application of safety standards EN ISO13849-1 and EN 62061

- use of the "Safety Integrated" feature from Siemens

- latest generation of controls SINUMERIK 840D sl

- operation identical to a new machine (Sinumerik Operate)

- modular drive technology for Sinamics S120 for higher levels of dynamism and accuracy

- latest technology cycles/automated measuring cycles

- optional: maintenance and diagnostics facilities during the machining operation thanks to the new fluidics module

- standardisation with HELLER specification

- continued use of existing tool sets

- continued use of existing fixtures and pallets

- compatible with any existing loading system

- HELLER BLUE energy efficiency

- other options (e.g. measuring probe, tool break monitoring, etc.) can be installed

- scope can be adapted to suit the customer's budget

Our services

Control retrofit

Rebuild to the latest control technology and activation of the associated performance increase by up to 15%.

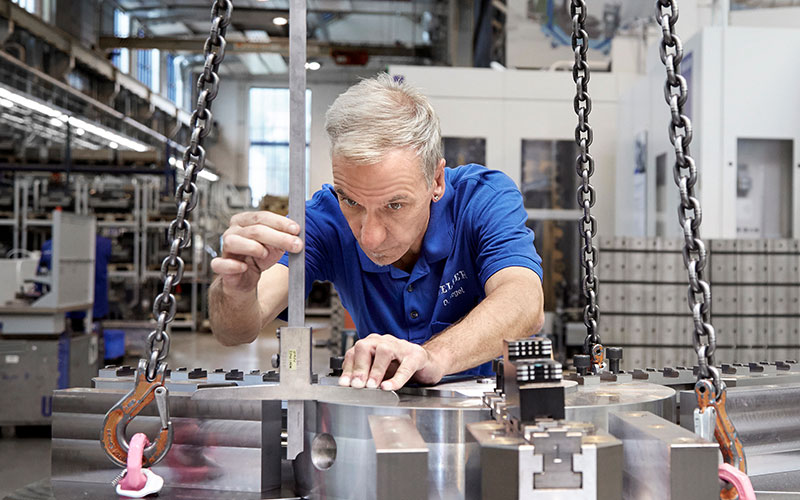

Machine retrofit

HELLER Quality

Control retrofit and restoring productivity by overhauling all machine components to reflect fair market value.

Machine retrofit

HELLER Premium

Complete retrofit, including control, and integration of all available technical upgrades, as well as replacement of all wearing parts.

If you want a control retrofit or cost-optimised machine overhaul tailored to your needs, HELLER Retrofit – sometimes in collaboration with cooperation partners – is happy to lend its support and make an offer.

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!