HELLER solutions at Olocco

Improvement of the cycle time and quality of the parts

Founded in 1950 in Fossano, Olocco S.r.l. produce rotary valves, diverting valves and conveying/dosing components and has always designed and manufactured its own products. With special treating versions they are able to respond to every request of the market, from food, plastics, chemical, pharmaceutical and construction materials. Starting from 2014, the customer decided to renew and increase the machining centres in his own production to improve product flexibility and quality.

Task

- production of different types of pieces with low volumes

- machining of aluminum and steel parts

- possibility to use bridge boring bars for large diameters

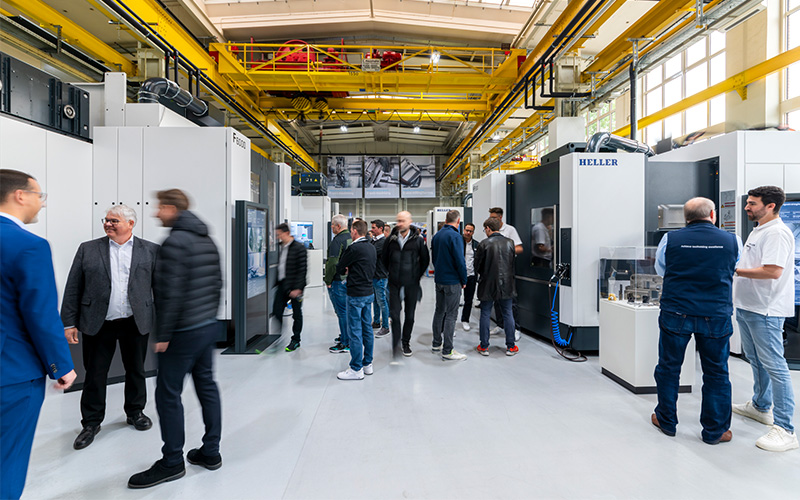

Project scope & solution

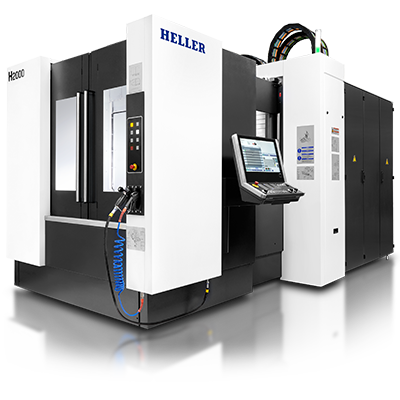

- 4-axis machining centre H 4500 with unit for aluminum parts, and HSK-A 100 tool shank for high machining rigidity

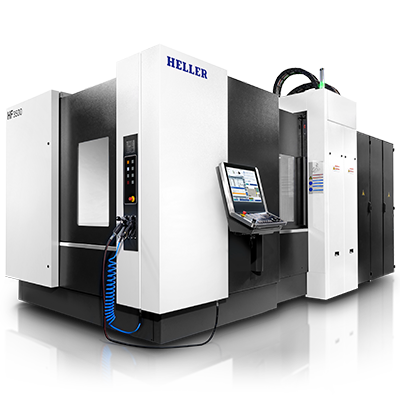

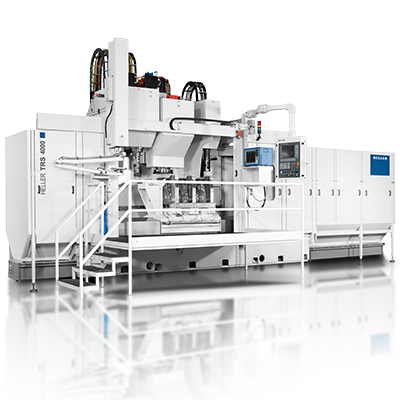

- flexible production system with one 4-axis machining centre H 5000 and one pallet handling system Fastems FPC 1500 with 10 storage places

- 4-axis machining centre H 5000 (stand-alone machine) for the production of steel parts

- magazine for tools of high length and diameter

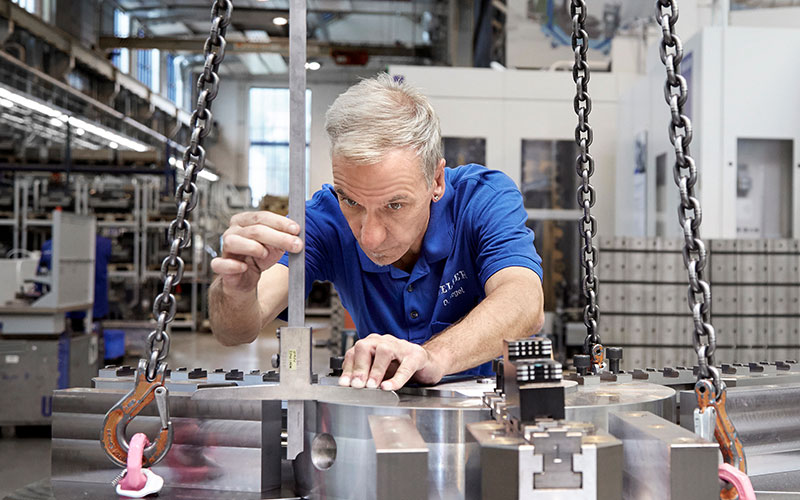

Result

- improvement of the cycle time and quality of the parts thanks to the use of a latest generation machine

- highly flexible production

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!